On March18th, 2024, an customer from Indonesia inquired the upgrading of organic fertilizer production system.He had drum granulation line that making fertilizer granules from organic waste. Including cms, a waste from a monosodium glutamate factory and some solid raw materials. Here, the key requirements of the Indonesia customer is granulation rate improvement. For this, we finally designed a 3 t/h pan granulation line for him. The following are the specific details of this case:

Organic Fertilizer Granulation Line

- Country: Indonesia

- Capacity: 3 t/h

- Material: cms, monosodium glutamate factory waste, etc

- Rquirements: Granulation rate improvement

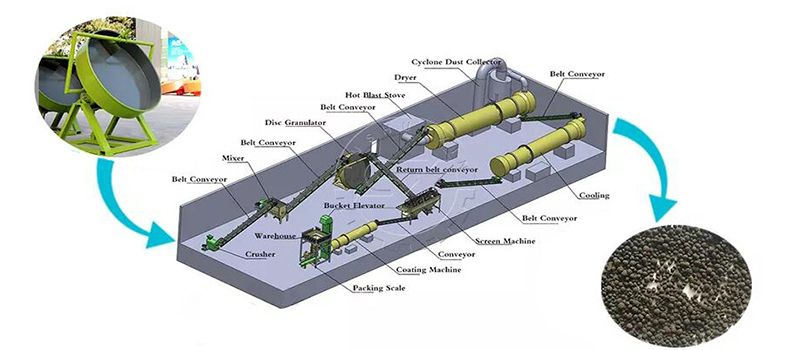

- Solution: Pan graulator production line

How to improve the granulation rate of drum granulation line?

As mentioned above, the customer from Indonesia required an 3 t/h organic fertilizer production line with higher granulation rate. In the past, the client prepare organic fertilizer into granules by rotary drum pelletizer. However, the granulation rate is only 60%. For this, we can offer you 2 solutions:

Adding a pan disc granulator after drum pellet machine

For one thing, our disc pellet equipment has a high granulation rate – 93%. This can improve the low granulation rate of the old organic fertilizer manufacturing machines. For another, with drum and pan dual granulation processes, you can granulate more organic material powder into pellets. Namely, the fertilizer granule making rate can be higher than 93%.

Replacing drum pelletizer with disc granulator or new type granulator

In addition, you can choose to replace the drum pellet machine with the another with a higher granulation rate. For this, pan granulation machine is an ideal choice. 93% granulation rate, round granule making and a economical price. However, if it is not enough, there is also new type organic fertilizer granulation equipment for you. Its fertilizer powder granulation rate can reach 97%. Moreover, the machine can bring you fertilizer pellet with a higher hardness, which is beneficial for eaiser to transport, store and use.

Finally, considering the workshop area, the Indonesian client prefer to pan pellet machine. And he planned to setup a pan granulation line.

Is there method to prevent erosion to pan granulation Line?

Then, because of no rubber lining, the old drum pellet equipment had been eroded. So, the customer wanted to know how to prevent the fertilizer making erosion to pan pelletizer system.

On the one hand, we can help you add wear-resistant plates to the disc, which is 304 stainless steel. Durable and wear-resistant.

On the other hand, this a scraper on the top of the disc. It can remove the material that is stick to the equipment and reduce the possibility of machine erosion.

Learn more about pan granulation line of organic fertilizer !

How to separate nonstandard size organic fertilizer granules for reuse?

For this, you can process the organic fertilizer granules with rotary screening machine after pan granulation. It can divide the granulated organic fertilizer into 3 parts: small particles and powder, required size granules, large fertilizer pellets. Then, the standard size granular organic fertilizer will be transported to the next step. At the same time, you can return the nonstandard size pellets to crush and granulate again.

The above are details about our communication with the customer about 3t/h pan granulator production line in Indonesia. Besides, we can also offer you many other organic fertilizer making business plans. Such as system of fertilizer composting system, fertilizer drying system, etc.

Error: Contact form not found.