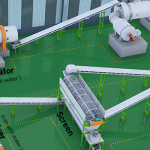

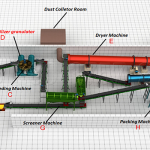

When you want to build a large-scale organic fertilizer or compound fertilizer production line, in addition to the compost turners, you need to buy a quality fertilizer granulator. But which pellet machine is suitable for high-volume fertilizer manufacturers? The answer is the rotary granulator machine. Its maximum output can reach 30 t/h. It sounds incredible. In fact, the drum granulator is one of our best-selling fertilizer granule making equipment. What makes the rotary drum granulators so popular?

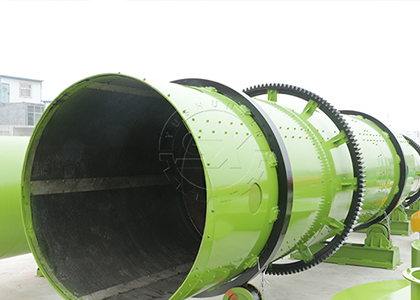

What is the structure of Our Fertilizer Rotary Granulator Machine?

In order to use rotary drum granulator freely to produce high quality organic & compound fertilizer, it is advisable to learn the design in details. Generally, a drum fertilizer pellet machine consists of the follow 4 parts.

Driving Device

The drive system of the rotary drum granulator mainly includes a motor, a reducer and a drive roller. The motor powers the rotation of the drum. The motor output is decelerated through the reduction gear, and the drum is driven to rotate through the reduction gear.

Rotary Drum

The drum is a pelletizing container. It is a cylindrical shape and its material is steel plate. It has a rubber plate attached to the inside to prevent highly viscous materials from sticking to the cylinder wall. The length and diameter of the drum depend on the quality requirements of the granulated material and the quality requirements of the granulated particles.

Gear Teeth

The gear teeth mainly include two parts, large gear guard and riding ring. The large gear guard is fixed on the rotary drum. Its main function is to maintain the position of the rotary drum. The riding ring is connected to the riding ring support, symmetrical on both sides of the drum. Its main function is to rotate the drum.

Machine Base

The drum granulator has a stable rectangular base. You should put it on a flat concrete floor. The machine base connects to the riding ring support on both sides to ensure the stable operation of the machine.

Contact use for your own organic fertilizer making system immediately!

top 3 Innovative Design of SX Rotary Drum Granulation machine

From the feedback of our past customers, it is obvious that rotary drum granulation equipment is popular with them. Why? Because this fertilizer pellet machine has some special designs that make industrial fertilizer granule manufacturing easier. Whether it is an organic fertilizer production line or a compound fertilizer production line.

Granulator Drum’s Hammering Cleaning System

Given that the rotary drum granulator is wet granulation, the raw material after adding water will inevitably stick to the inner wall of the rotating drum easily. This not only wastes raw materials, but also corrodes the inner wall over time. So we set up round holes on the outside of the drum. During fertilizer production, you can use hammers to hit the round holes. The raw material sticking to the inner wall will peel off by vibration. On the one hand, can clean the inner wall like a cleaning device and keep the inside of the drum clean; On the other hand, it reduces the consumption of raw materials.

Using Stainless Steel Pressure stripes

There is a rubber plate inside the rotary drum granulator to prevent it from sticking to the wall. And our rubber plate is covered with stainless steel pressure lines, which effectively fixes the rubber plate. Because it is stainless steel, it will not corrode. Overall, it makes the machine last longer.

One Molding Spiral Tube

The most important part of a rotary drum granulator is its drum. So what is the unique design of our rotary drum granulator? The answer lies in the one molding spiral tube used for our drums. The thickness of each place is the same, so there is no need to worry about cutting corners. When the drum is running at high speed, the quality of the drum is particularly important. The rotary drum material is Q235B boiler carbon steel, which has high strength and not easily deformed characteristics.

Why are Drum Granulators Favored in Large Fertilizer Granule Production Lines?

Large Output

the minimum output of the drum granulator is 1-3 t/h, and the maximum output can reach 15-30 t/h. It can fully meet the requirements of both small and large scale granulation production.

Enclosed Granulation

The whole process of rotary drum granulation is carried out in the drum, so there is no need to worry about the problem of powder sedimentation. It also means that in closed environments, raw materials are less prone to waste.

Low Energy Consumption

When choosing a granulator, energy consumption is also an important factor to consider. The motor and reducer of our drum granulator are from domestic brands with low energy consumption, which can help you save costs.

3 Hot-Selling Rotary Drum Granulators In sX

NPK compound fertilizer rotary drum granulator

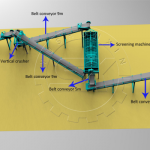

NPK fertilizers contain nutrients needed for healthy crop development. Its main ingredients are nitrogen, phosphorus and potassium. And named after the abbreviations for these substances. So how to granulate npk compound fertilizer? Drum granulator is the best machine for NPK fertilizer production. First, you need to mix the raw powder containing NPK and other nutrients well. Second, you should add water or steam to provide bonding conditions. Finally, it is agglomerated into granules through the high-speed rotation of the drum granulator. Generally speaking, the production line for making NPK fertilizer has a large processing capacity, and a high-yield drum granulator is the best choice.

Organic fertilizer rotary granulator machine

What do you do when you have a pile of animal waste? Maybe you have the idea of making organic fertilizers in your head. In addition to composting, granulation is an important step in making organic fertilizers. Whether it is cow manure, pig manure, sheep manure, chicken manure or horse manure, etc, you can granulate with a drum granulator. Due to its high output, many manure organic fertilizer production lines have chosen the drum granulator. We have different output drum granulators for you to choose, you can choose the appropriate type of drum granulator according to the scale of your production line.

High output rotary granulator machine

The production capacity of our rotary drum granulator is between 1-30 t/h. Whether you are a small fertilizer producer or a large fertilizer producer, our drum granulator can meet your production needs. Compared with disc granulators, drum granulators have higher output. It is more suitable for the production of large-scale organic fertilizers and compound fertilizers.

Main technical parameters of SX drum granulation machine

| Model | Power (kw) | Diameter (mm) | Length (mm) | Installation Angle | Rotary Speed (r/min) | Capacity (t/h) |

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9.5 | 15-30 |

How to Choose the Right Rotary Drum Granulator?

Choose a Formal Enterprise

As a mature organic fertilizer equipment manufacturer, after more than ten years of development, we have achieved one-stop services such as design, manufacture, installation, commissioning and technical training. Over the years, our equipment has been exported to many overseas countries, and our products have been distributed in China and all over the world. You can fully trust our enterprise.

Choose Sturdy and Durable Materials

Our products have developed with the development of the times and have obtained many new utility patent certificates. We also continue to absorb various foreign precision accessories, such as Siemens, ABB, etc., to make our equipment last longer and more stable. In the performance of the rotary drum granulator material, we have a great advantage.

Choose the Right Price

Compared with the high prices in countries such as Europe, our equipment has a great price advantage. During some holidays and the end of the year, we will give discounts. And we are happy to send you some specialties from China. So if you are interested in our rotary drum granulator, contact us!

Error: Contact form not found.