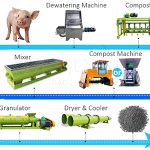

If you want to make organic fertilizer, suitable equipment is necessary. As leading and reliable fertilizer equipment manufacturer, SX can provide you with various organic fertilizer production equipment for your choice.

Solid-liquid separator machine

Our separator aims to reduce the water content of animal waste to an ideal level, so the process of fertilizer composting can complete quickly. According to different models, the capacity varies. We recommended the SXTS-230, with a capacity of 20 square meters per hour.

Why do you need a separator? Why not dry manure naturally, like drying it in the sun?

We highly recommend you to use our solid-liquid separator to treat your organic fertilizer making materials. Especially when you use fresh pig manure as fertilizer, because it has a high moisture content. If you pile manure up in the sun, it is prone to create an anaerobic environment that causes unbearable reek. And the whole process of drying heavily depends on the weather that is volatile sometimes.

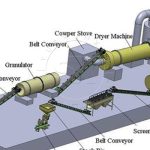

Groove type compost turner

Compost machine play an important role in organic fertilizer manufacturing. It is the key to speed up the compost of organic waste, which is a process of harmless. Here, we can offer you groove type compost turner, windrow compost turner, in-vessel composter. Among them, groove type composter is recommended. Because it can meet your general requirements of organic fertilizer preparation and has a economical price.

How about windrow compost turner and in-vessel fermenter? What is the difference between them?

Windrow compost equipment can start fertilizer compost on flat ground directly. There is no expense on fermentation groove building. But if you prefer to high automation composter and want to decompose manure quickly, in-vessel fermentation tank is the best choice. It equip with computer control system, which can offer you a fully automatic composting process. In addition, because of closed environment fermentation, it can compost fertilizer faster.

What is the turning depth of your groove type machine?

There are 4 types, namely 0.8 m, 1.0 m, 1.2 m, 1.5 m. According to your requirements, we can customize it for you.

What is the material of that compost turner’s turning teeth?

It is 16 Mn steel, a kind of durable steel.

Contact use for your own organic fertilizer making system immediately!

Vertical crusher

Why do you need to crush compost? In the process of composting, material will combine with each other because of high moisture content. This is not beneficial for further organic fertilizer processing. Therefore, you need to crush it into small powder. The capacity of our vertical crusher is much larger than other crushing machines on the market, close to 15 tons per hour. Besides, it is not easy to block when grinding high moisture materials, like cow manure.

Rotary screening machine

To produce pure biofertilizer pellets, it is necessary to screen out unwonted materials, such as little rocks. The sieve of our screener is made of galvanized steel whose service life is much longer.

Will it cause dust or powder?

No, there is a plate used to prevent dust or powder from flying. It won’t lead to air pollution. Or we can equip it with a dust cover.

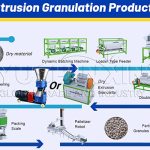

Dynamic batching machine

In organic fertilizer production, we usually use various organic materials. This is the secrete of preparing higher quality organic fertilizer. In this process, feeding proportion is essential. But dynamic batching machine can strictly feed various raw materials according to required proportion. Even you want to add bacteria for bio fertilizer manufacturing. Because it has electrical weighting system and quality belt conveyor. In addition, we equip it with material hoppers according to your needs.

Contact use for your own organic fertilizer making system immediately!

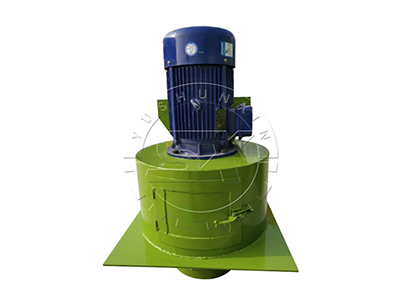

Horizontal mixer

How can you make good organic fertilizer products without blending raw materials well? Carried by our automatic conveyor, each raw material is fed into a horizontal mixer which will blend it thoroughly and evenly by the blades.

How long can you get the final mixture after using this machine?

It won’t take too much time to blend your materials. Within 5 minutes, you can get well mixed fertilizer powder.

What is the material of the blades?

It is manganese steel, an excellent material for crushing and mixing parts.

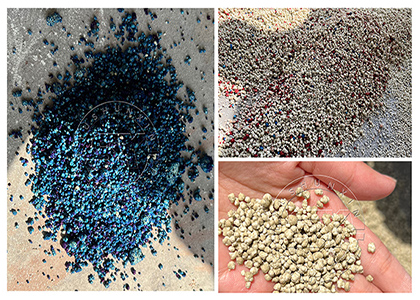

Organic fertilizer Granulation machine

In commercial organic fertilizer making, make organic fertilizer into pellet can help you make more profits. There are many types of organic fertilizer granulators for you choice. Disc granulator for small scale and low cost fertilizer pellets making. New type organic fertilizer pelletizer for high hardness manure fertilizer granules making. Rotary drum granulation machine for large scale organic fertilizer granulation. Etc. They can fully meet your requirements for making granular organic fertilizer.

What is the input and output moisture?

It is 30% and 15% respectively.

What is the stirring tooth made of?

It is Manganese steel, a durable material.

How to change them when they are broken?

I will send a maintenance book to your e-mail. You can easily change them under the guidance written in that book.

Do you need a polishing machine?

No, you don’t. Biofertilizer pellets made by our rotary drum churning machine look good in shape and appearance. You do not need to spend more money to buy a polishing machine.

Rotary screening machine and Chain crusher

This screener is used for screening unqualified organic waste fertilizer pellets, so that the high quality of bio fertilizer products can be ensured. After granule screening machine, we usually design a chain crusher for these pellets. In commercial fertilizer production plants where tons of fertilizer pellets are produced daily. The amount of unqualified pellets is also huge and will cause enormous economic damage. So it needs a chain grinder to crush them in powder for regranulating.

What is the difference between there 2 crushing machines on my production line? Can I use the first crusher to dispose of unqualified pellets?

The first is for crushing compost, while the second, for unqualified biofertilizer pellets only. It is not sensible to use one crusher for crushing compost and fertilizer pellets. Your production line may be complex if you insist on it.

Can you use other grinding machines for unqualified bio fertilizer pellets?

Our chain crusher is designed for unqualified fertilizer pellets only. The efficiency of crushing will not reach your standard if you use other grinders.

Rotary drum dryer and rotary drum cooler

After organic fertilizer granulation, the moisture content is about 20%. This is not high, but it is still easy to causefertilizer caking, a negative factor for the quality of fertilizer. So you need to add a dryer to your manure fertilizer production line. As for the cooler, it is used to cool dried fertilizer pellets, so the caking problem will not happen easily. Moreover, we also can provide you with dust collector, where aims at treating dust or powder created in the drying process.

How long is the process of drying or cooling?

It only takes a few minutes. We can prolong or shorten that process by adjusting the inclination of the machine.

What is the fertilizer caking problem?

It is a phenomenon that your fertilizer pellets stick together, which adversely affects the quality of fertilizer and increases the difficulty of mechanical fertilizing.

Auto Bagging machine

An automatic bagging machine is indispensable in setting up an ideal organic fertilizer production line. Controlled by a PLC system, our packing equipment is able to realize the automation of weighing, bagging and sealing.

How many workers do you need in the process of bagging?

One is enough.

Is there any silo provided over the packing machine? And what is the capacity?

Yes, there is a small silo, with a capacity of 0.3 m³.

What is the scope of your packing machine?

Its packing weight range within 500-2000 kg.

Error: Contact form not found.