Is it possible to compost organic fertilizer in an enclosed environment? Of course. Composting in enclosed environment, is known as in vessel fermentation, is also a form of fast aerobic composting. It will isolate the influences from outside world to facilitate the composting of organic waste. But how does in vessel composting machine create aerobic conditions for raw materials to ferment? How does the whole fermentation tank work? Come to get the answers all you want to know.

How does in vessel composting machine work to ferment organic waste?

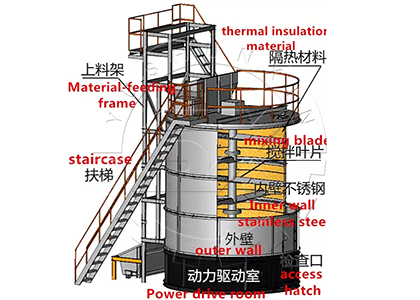

With the following constructure, organic fertilizer fermentation tank can finish manure composting easily.

Tank body

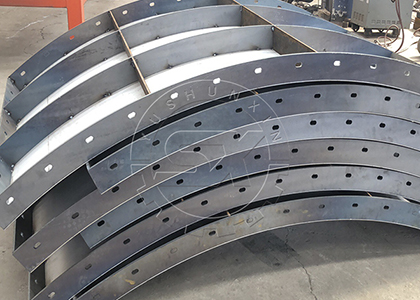

The fermenter should have a suitable diameter-to-height ratio, generally 1:2.5~4. The entire body of the tank is generally a cylinder, and the material is carbon or stainless steel. Large-scale fermentation tanks adopts lined stainless steel or composite stainless steel as materials. The thickness of stainless steel is generally 2~3 mm. Moreover, there is an insulation layer in the middle, the thickness can adjust according to the outside temperature. The outer walls are generally supported by thickened plates of steel. Therefore, it can greatly reduce the outside world influences to facilitate your composting. In addition, the top and body of the small fermentation tank are generally connected by flanges for easy cleaning.

Ventilation pump

It mainly provides the oxygen supply in the fermentation tank, and the outside air enters the fermentation tank through high pressure to fully contact the fermentation material. Increased aerobic conditions.

Mixing blades

The agitator can stir the materials in the fermenter evenly. The mixing blades constantly agitate your organic materials to make them fully contact with oxygen.

Exhaust gas treatment system

Considering the smell problem, we added exhaust gas treatment device. Namely, during the fermentation process, the waste gas and dust pollution generated can be sprayed and purified to avoid unpleasant smell and pollution.

Why In Vessel Composting Machine Can Ferment Fertilizer Quickly?

Feeding device

The feeding apparatus consists mainly of an automatic dump bucket elevator. During the feeding process, the hoist carrying the raw material moves upward automatically and pours the raw material into the fermenter. No need for manual feeding, which reduces the workload.

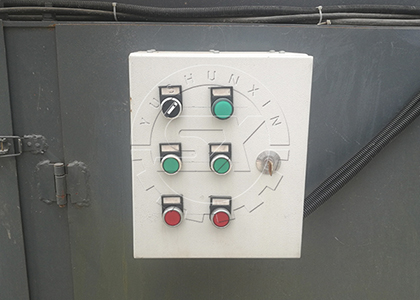

Control system

The control cabinet can detect the temperature and fermentation process in the fermenter. The entire fermentation process only needs to be operated by the control cabinet.

Automatic discharge device

You can automatically control the output of organic fertilizer, and can automatically discharge the fermented material out of the fermenter. So you can finish industrial organic fertilizer compost making easily and quickly.

Contact use for your own organic fertilizer making system immediately!

2 Designs to speed up your organic waste composting

oxygen heating

In the upper side of the fermentation tank, the heating device will also heat the oxygen that is pressured into the tank to make sure the fermentation tank has suitable temperature.

Aeration holes design

On the mixing shaft, we especially design many aeration holes. They are greatly beneficial for increase the breathability and heat dissipation. So you can compost manure faster, only 7 days.

How To Maintain The Organic Fertilizer Fermentation Tank?

Stairwell

The larger organic fertilizer fermentation tanks are equipped with a stairway device to facilitate workers to reach the top of the tanks to observe the feeding.

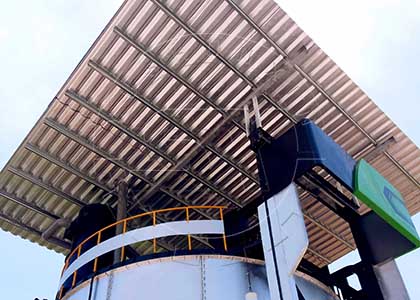

Shelter

A shelter is built on the top of the fermentation tank to avoid the erosion of the fermentation tank by bad weather. At the same time, it is convenient for workers to work on rainy and snowy days.

Detection platform

There is a maintenance and inspection platform up the stairs. On the one hand, you can observe the operation of the machine and the fermentation status of the material. On the other hand, it is convenient for the workers to carry out repairs.

3 Best-Selling Organic Fertilizer Fermentation Tanks

Chicken Manure In Vessel Composting Machine

Owners of small chicken farms prefer small compost machines to help them dispose of chicken coop waste. Our small organic manure fermenting tank requires only six cubic metres of land, you only need to put it next to your chicken coop and you can achieve chicken manure composting without a large footprint.

Three-dimensional design saves land: For fertilizer plants with a small land planning area, the organic fertilizer fermentation tank does not need a large space, saving your land rent.

Electrical control: Place a fermenter next to your chicken coop, and only 1-2 workers are needed to complete the composting and fermentation of your chicken manure.

Cow Dung In Vessel Composting Machine

How do you compost your cow manure without being affected by the cold weather, and also in bad weather? You can try our organic fertilizer fermenter. Our organic manure fermenter was designed with environmental considerations in mind. Using it, you can make compost all years. The fermenter body consists of a stainless steel liner and an outermost shell. However, between these two layers of material we placed a thermal insulation layer. Prevent fermentation from being affected by cold or humidity in the external environment. In Russia, the cold weather outside has prevented the composting temperature from increasing. But our commercial fermenters can help keep your compost out of the cold outside.

Pig Manure In Vessel Composting Machine

Are you planning a project on organic fertilizer from pig manure?Have you ever thought about how to quickly compost your pig manure? The entire fermentation process takes only 15 to 20 days, and you can get fermented pig manure piles. The temperature of the fermented pig dung no longer rises, there is no unpleasant smell, and the particles are finer and more soft. The fermenting pig manure pile will have less than 10% moisture and a pH of between 6-8. Come to look the in vessel compost machine.

If you do not know how to choose a fermenter with a large volume, you can ask us and we will customize the capacity of the fermenter based on

the amount of your ingredients.

What you need to do before start in-vessel fermentation of organic waste?

You will need to dehydrate your pig manure before putting it in the fermenter. The ideal moisture content for fermented ingredients is 50-60%, but general poultry manure has a moisture content of about 70%. So you need to add some agricultural waste such as straw, sawdust, hay, etc. to reduce the moisture content. On the other hand, you can dehydrate your manure with the help of a dehydrator, but this will reduce your manure production.