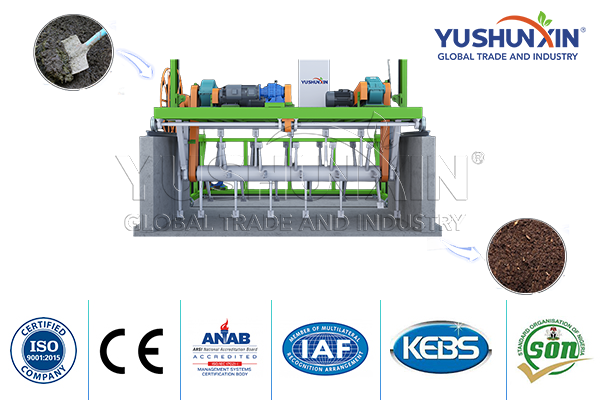

The groove type compost turner is an efficient composting machine designed for large-scale organic waste management. Mounted on rails lining composting grooves, this machine mechanically turns and aerates organic materials. Like agricultural residues, animal manure, and municipal waste. Its rotating blades mix the compost piles thoroughly, promoting aerobic decomposition by enhancing oxygen contect and evenly distributing microorganisms. This process accelerates compost maturation, ensures homogeneous decomposition. So it is indispensable for commercial composting operations seeking to dispose of organic waste quickly and produce nutrient-rich fertilizer effectively and sustainably.

Groove Type Compost Machine

- Turning Width: 2.5-5 m

- Turning Depth: 0.8-2 m

- Equipment Material: Carbon steel Q235, Alloy

- Composting Time: 15-20 days

- Methods: Aerobic fementation, Trench type composting

- Application: organic waste disposal, compost fertilizer making

How does a Groove Type Compost Turner Work?

As the name suggests, the fertilizer compost machine is working with fermentation groove. The groove compost turner will walk forward and backward by on the trench along the fermentation trench. At the same time, the turning shaft with teeth will rotating at high speed to turn the materials in the trench to break and throw them backwards. In the process, the turning makes the organic manure fully contact the air. Not only can increase the oxygen content of the accumulation, but evaporate the excess water and reduces the temperature of the accumulated material. So you can keep the temperature between 60℃-70℃, which makes the organic waste compost quickly.

How to Use a Compost Trench Turner

3 steps you need to do before trench composting

First of all, to use the groove type turner, it is necessary to build a trench, one machine with one trench or one machine with multiple trenches. Secondly, you should pile the raw materials such as manure, biogas residue, straw and so on in the trench. Thirdly, you should mix the bio-organic fertilizer fermentation bacteria in the raw material pile, then it is time to use the groove type turner.

Electronic control groove compost making operations

Do not worry! The groove turner for composting uses an electronic control system, which is simple and convenient to operate. It has a remote control, which can be automatic or manual. When the main engine starts to run, you should turn the rotary button to the “automatic” state to open the walking button, then the trench machine starts to work. Next,under the action of the vertical and horizontal walking mechanisms, the fermented materials turn and displace in the pool, forming a continuous aerobic fermentation process. So it may be easier to operate than you think.

4 Key Components Groove Type Compost Turner

To make the groove type compost machine work successfully decompose organic waste, the whole compost contains 4 key parts.

- turning teeth: As the name suggests, this part is key to turn compost piles to facilitate the aerobic fermentation. The tuning teeth are made of 16Mn, strong and durable. You only need to replace it once every 0.5-1 year。

- Walk system: The groove compost machine need to walk on the fermentation trench to treat all organic waste inside. How does the groove compostor move? It mainly relies the rails and electric cable winding wheel.

- Groove changing device: Then, after completing the turning of compost in one fermentation trench, how to move to the other? There is groove changing device for you. It help you change compost groove easily.

- Control panel: Finally, Control panel is indispensable for groove composting. It is key to improve the automation of the compost equipment. Only need to preset the speed and working time, the machine can compost organic manure without any other operation.

4 Advantages of Groove Type Composting Machine

- Small investment: In all organic compost machines, the groove type compost turning machine is the best economical one. Eapecially for small scale compost making project. The price of groove type compost turner is only $5,000-$19,000.

- Easy to operate: Automatic control cabinet design, no need for personnel to operate it at close range. So, you only need to transport organic manure to fermentation trenches. Finally, transport composted manure from the grooves.

- Wide capacity range: The organic waste processing volume of the groove compost equipment depends on the length and number of trenches, and the processing capacity of the equipment is large.

- Suitable for various organic waste management: The composter can process many kinds of organic materials, animal manure, straw, sludge, medicinal residue, biogas residue, etc.

What you need to focus on in groove organic fertilizer composting?

If you want to make quality compost fertilizer with groove compost equipment, there are two tips for you.

Adjust moisture before groove compost making

what you need to know before composting is that you cannot pile the pure animal manure directly in the trench for composting.

Because the water content of different materials is not the same, when the material enters the trench, the water content of the material should be between 50% and 60%. But if it reaches 70 to 80 percent, it is necessary to add auxiliary materials, so use agricultural waste straws, sawdust, etc. for matching to reduce the water content and increase the organic matter content.

Keep the groove compost temperature at 60%-70%

The best raw material fermentation temperature range is 60-70 degrees. When the raw material temperature is above 70 degrees, you need to start turn material, you can use a thermometer to detect the temperature.

How Long Does Trench Composting Take?

When fermenting in the trench, you should turn once a day until the temperature stops rising and starts to drop. Usually this process need 15-20 days. When the temperature of compost material no longer rises and there is no odor in manure waste, the compost process is completed. Because, in the process of groove fermentation, it can prevent the production of harmful and malodorous gases such as hydrogen sulfide and amine gas in the feces.

The Difference between Trench Composting and Window Composting

Trench composting and window composting are two commonly used composting fermentation processes.

Window Composting

Window composting is to spread the materials into strips and stack them in the open air or under scaffolding. What are the characteristics of window composting? The characteristic of window composting is that the materials can be placed closer to the farmland. No special workshop is required, but the processing time is limited. If the open-air method is used, it will be greatly affected by the season. Compared with other composting methods, window composting has a relatively simple process and small capital investment. It is suitable for small farms in rural areas. However, it covers a large area, is not fully decomposed, and causes serious secondary pollution.

Trench Composting

The trench composting is more suitable for large-scale organic fertilizer manufacturers or large-scale animal farms. They have large input and output. So it is suitable for commercial industrialization and large-scale production. The product quality is high, and the environmental pollution is small. In addition, trench composting is less affected by weather and seasons. It can be turned all year round, while window composting is greatly affected by season.

So, if you have a large animal farm or a large organic fertilizer manufacturing plant, build a trench! And the groove type compost turner is the best choice for you. Helping you save manpower and material resources. Teaching you make good use of your organic manure. This is not only a problem of production, but also protects the environment. You can completely trust our equipment. We constantly integrate advanced accessories at home and abroad, such as Siemens, Schneider, ABB, etc. We also attach great importance to the improvement of equipment quality, constantly develop new products, and have obtained many patent certificates. After more than ten years of development, our customers are all over the world. We have also received many customers visiting from abroad, like India, Uzbekistan, Switzerland, Sri Lanka. And on many holidays, we have big discounts. Compared with other countries, our prices have certain advantages. If you are interested in our groove type compost turner, please contact us to help you solve the problems!