What equipment is suitable for dried organic manure granule making?

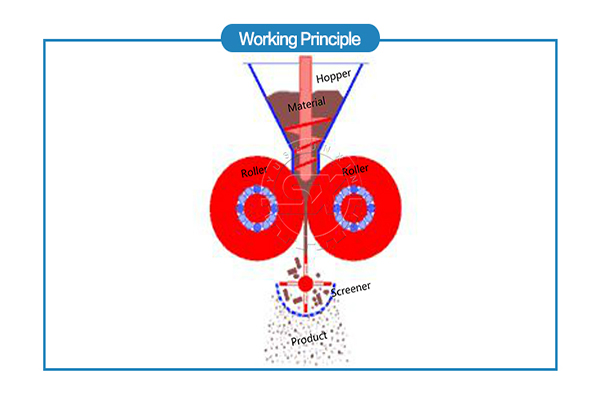

The double roller granulator also play a important role in organic fertilizer making. It can help you make powdered dried organic manure into dense, uniform fertilizer granules. It operates by pressing the organic material powder between two rotating rollers that mold the material into a pellet shape. In this process, there is no water needed and organic compost can convert into pellets only by one time compressing. Therefore, you can prepare organic fertilizer granule from dried manure quickly and with a high granulation rate.

Double roller granulator for sale

- Capacity: 1-3 t/h

- Granule size: 1-10 mm

- Feeding moisture: 5%-10%

- Power: 15-22 kw

- Application: Dired manure waste, chemical powder

How does the roller granulator work to turn organic and compound fertilizer pellets?

The roller granulator functions by feeding powdered organic or compound fertilizers between two counter-rotating rollers that are embossed with molds. As the material enters the rollers, it is compacted under immense pressure into a dense sheet. The pressure causes the powder particles to fuse together, creating a solid mass. This sheet is then broken into smaller, jagged pieces or directly cut into the desired pellet size, depending on the granulator design. The resulting pellets are then often rounded through additional equipment for a more uniform shape. This process does not require any liquid binder, as the pressure alone is sufficient to bind the particles together, making it an efficient and cost-effective method for producing fertilizer pellets.

What is the Unique Design of Double Roller Granulator?

Our double roller fertilizer granulator basically consists of driving device, feed port, roller sheets, discharge port, etc. But what are the uniqueness of the double roller press granulator that make it hot selling with international fertilizer manufacturers? The answer is that we have higher demands on the material and design of our machines. It is precisely for these reasons that our roller extrusion granulator has become the preferred granulation equipment for organic fertilizer production and compound fertilizer making in recent years.

What is material of the double roller press machine?

In order to make the double roller has a longer service life for your fertilizer pellet making, we especially upgrade the material. The main body of the fertilizer granule making equipment adopts boiler steel- carbon steel Q235, which has excellent strength. As for roller sheets, which are contact with organic waste and chemical material for a long time. We especially replace with 20 CrMnTi, which is a well-performing carburized steel. It is highly hardenable and can withstand high loads and impact forces. So, it is the material of many parts of automobiles and airplanes.

Unique designs of double roller granulation equipment

Feed port and discharge port

The feeding port is on the top of the main machine, which is convenient for feeding. At the same time, discharge ports is located in side. This is beneficial for reducing the area occupation and start organic fertilizer pellet preparation and NPK compound fertilizer granules manufacturing.

Driving Device

The driving device of our roller extrusion granulator uses electric motor and reducer with low power consumption. We can save the cost to the greatest extent for you. When purchasing a granulator, the motor power consumption are also a factor that you should consider. Therefore, in the selection of our motors, we use well-known brand motors, which have low power consumption and stable operation.

Why Most Fertilizer Manufacturers Choose Our Double Roller Extrusion Granulators?

No Need for Additional Adhesive and quickly fertilizer pellet making

The highlight of the roller extrusion granulator lies in its granulation method – dry granulation. Differing from wet granulation method, it makes use of extrusion force between two rollers to granulate dried manure into organic fertilizer granules. Without additional binders, this makes fertilizer granulation quickly and simpler. In addition, it reduces energy consumption and saves the drying cost.

High Granulation Rate and high hardness fertilizer granules making

Because of roller compaction granulation method, it can turn more material into fertilizer pellets. The granulation rate can reach 95%. At the same time, the produced fertilizer granules has a high hardness – 15-20 N. Therefore, the final fertilizer granules are easier to transport and store.

Easy operation to enlarge organic fertilizer making scale

Only needs to put the mixed material into the feeding port, The double roller press granulator will press dry powder material into flat fertilizer granules without other operations. Moreover, when you want to change the final fertilizer pellets, only need to replace with roller sheet with corresponding size ball socket. What’s more, for further enlarge the fertilizer granulation scale latter, you only need to buy more double roller granulators.

Both for organic and compound fertilizer granule making

With advanced manufacturing technologies, it can fully meet your requirements of organic fertilizer pellet making and compound NPK fertilizer granule production. Including goat manure, chicken poop, swine waste, humus acid, ammonium chloride, nitrogen fertilizer, etc. However, what you need to focus on is that ensure the moisture of feeding material is lower than 10%.

Double roller extrusion machines parameters

| Model | Capacity (t/h) | Power (kw) | Granule Size (mm) | Roller Sheet Size (mm) | Dimension (mm) |

|---|---|---|---|---|---|

| SXDG-1T | 1 | 15 | 1-10 | 150*220 | 1450*800* 1450 |

| SXDG-1.5 T | 1.5 | 18.5 | 1-10 | 150*300 | 1450*850* 1500 |

| SXDG-2T | 2 | 22 | 1-10 | 185*300 | 1630*850* 1650 |

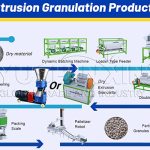

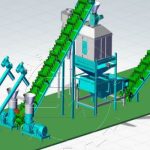

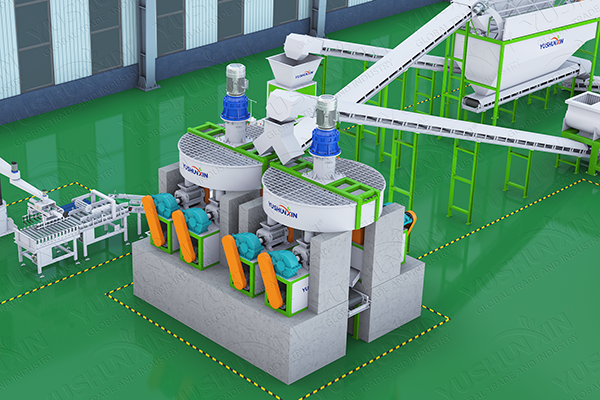

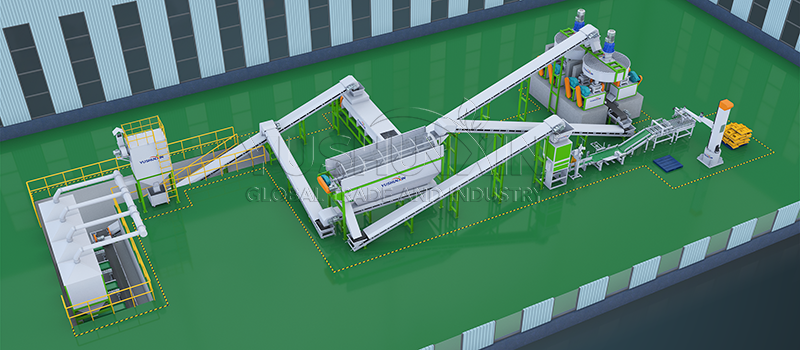

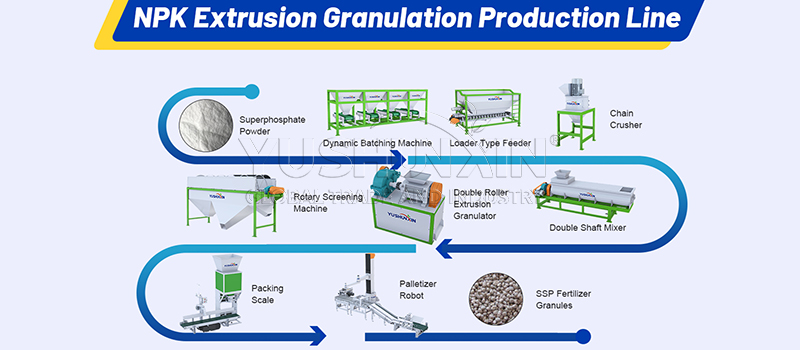

Profitable Dry Powder Extrusion Granulation Production Line

If you want to start industrial organic and chemical fertilizer granule making business, we recommend you setup a dry powder extrusion granulation production line with double roller pelletizer. It can efficiently process powdery materials into uniform fertilizer granules. This is also beneficial for optimizing material use and minimizing waste. It integrates batching machine, mixer, extrusion granulator, sieving machine and packing equipment.

Dynamic Batching Machine

When making compound fertilizer, you should mix a variety of raw materials. The dynamic batching machine is mainly fitting for mixing, batching and feeding of 3-8 kinds of materials. First of all, our dynamic batching machine can choose the number of bins. The most common is the four-bin batching machine. If you want to make compound fertilizer of several elements, you can choose several warehouses. Secondly, you can customize the size of our silo. Again, in terms of material, the contact part between the silo and the material is stainless steel. Finally, the dynamic batching machine is automatically controlled by a computer. And a pneumatic door is used to control the quantitative feeding of the main silo. After the material is mixed in the mixing bin, it is automatically sent out by the belt conveyor.

Double Shafts Horizontal Mixer

Why do you need to add a blender? This is because the material coming out of the batching machine is unevenly distributed. If you granulate directly, the distribution of nutrients in fertilizer granules is uneven. Some elements are abundant, and some are even missing. So the mixer is an indispensable step. Our double shafts horizontal mixer uses a double-shaft design to make the material more evenly mixed. Generally, after the dynamic batching machine, it is transported to the mixing tank by the belt conveyor. Homogeneous agitation is carried out by means of helical blades mounted on double shafts. It is worth mentioning that the spiral blades on the double shafts rotate in opposite directions, so that the machine can mix the material more evenly. The stirring blade is high-strength wear-resistant material, which has a longer service life.

Rotary Screening Machine

The granules made by the roller extrusion granulator have different shapes and sizes. The function of the screening machine is to sieve out the powder particles and the particles whose shape is not up to standard. The screen of our screening machine is stainless steel, which prevents the material from corroding the screen. And with hitting anti-stick net device. The overall structure of the screening machine is 150 seamless tubes as the legs, 3 mm iron plate as the box, channel steel as the frame, and 130 thick-walled seamless tubes as the shaft. In terms of material, it is tough and wear-resistant, and has a long service life. The powder screening machine has two discharge ports, one for finished products and one for waste products. The waste products are re-entered by the belt conveyor into the extrusion granulator for granulation. The finished product goes directly to the packaging process.

Belt Conveyor

Belt conveyor is an indispensable equipment for granulation production line. Mainly play the role of transport and connect each link. The belt of our conveyor is 4 layers canvas rubber belt with thickness 10 mm. The frame part adopts 10 mm international channel steel.

Packing Machine

The sieved particles can enter the final packaging process. Our packaging machines have an integrated design and are compact. Automatic packaging, quantitative weighing. The special design is that it can be fed and has bucket metering. The packing speed is fast and the packing precision is high.Using imported sensors, the measurement accuracy is plus or minus two thousandths.

How to maintain the fertilizer double roller pellet equipment?

- Maintaining the fertilizer double roller pellet equipment is essential for optimal performance and longevity.

- Uniform feeding is crucial; avoid under or overfeeding, and moderate the feed rate to ensure the resultant pellet quality.

- Prior to installation and operation, apply grease to wear-prone components like bearings to facilitate upkeep.

- Monitor the machine’s temperature and velocity diligently. Detect any stability issues and promptly examine the coupling gaps for excessive tightness, adjusting as needed.

- Always making the granulator rotate in a forward direction. In addition, ensuring it is running with materials feeded.

Besides double roller granulation equipment, there are also many other organic fertilizer pellet machines for your choice. Such as pan granulator for economical small scale fertilizer granulation, rotary drum pellet equipment for large scale fertilizer pellet making, new type organic fertilizer granulator for less dust fertilizer pelleting production,etc. Welcome to contact us for your own fertilizer granule production systems and machines.

Error: Contact form not found.