Swine manure management is essential for pig farm operation. It can dispose of manure waste to prevent pollution and diseases. Here, making swine manure into organic fertilizer is an ideal choice. In this way, you can make more profits form pig farm manure disposal. As a reliable fertilizer equipment manufacturer, SX can offer you all sets of manure fertilizer machines, various pig manure fertilizer making plans, economical price, etc to help you to turn pig waste into fertilizer as soon as possible.

What Equipment Does a Swine manure Organic Fertilizer Production Line Need?

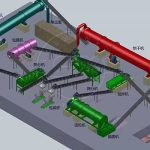

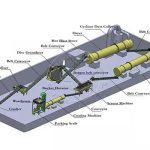

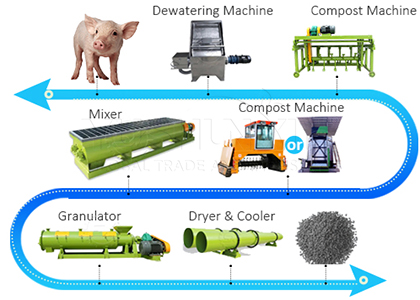

In general, a complete fertilizer making system for swine manure management contains equipment as follows:

Compost turner for pig manure harmless

For using swine waste as fertilizer, composting is necessary. Because of pathogens, pest eggs and grass seeds contained, you cannot make fresh pig manure into fertilizer directly. But with professional compost tuner, you can compost pig manure into harmless material within 20 days. Here, If you manage a small pig farm, the windrow compost turner is an excellent choice. But for large pig farm manure composting, it is advisable to buy a wheel type compost turner, which has a turning span between 8 m and 30 m.

Contact use for your own organic fertilizer making system immediately!

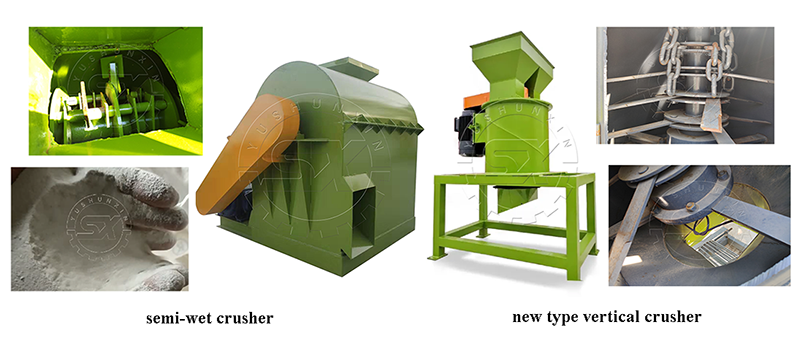

Crusher for organic fertilizer powder making

It is possible that your pig manure contains waste such as feed, food scraps, litter, etc. Then in the process of composting, the raw materials are easy to agglomerate. This is not beneficial for quality pig manure fertilizer making. At that time, you need to pulverize material into fine powder particles with suitable fertilizer crushers, such as vertical grinder or semi-wet crusher.

Mixer for blending swine poop with NPK evenly

We know that organic fertilizers have certain production standards. However, the nitrogen, phosphorus and potassium elements in pig manure cannot meet the requirements. So you need to add chicken manure or NPK materials directly the elements to enrich the nutrient content of pig manure fertilizer you produce. In addition, to ensure the final element balance of the fertilizer, it is necessary to mixing them with swine manure compost evenly with mixer.

Granulator for swine manure fertilizer compost to pellets

Materials with low fiber content, such as chicken manure and pig manure, are suitable for disc granulator. The materials with coarse fibers such as cow dung and sheep dung are suitable for the drum granulator and the stirring tooth granulator. A pan granulator can help you processing 0.5-6 tons of swine manure compost into organic fertilizer pellets. And only by using more disc pelletizers, you can finish larger scale swine manure management easily. In addition, it has features of economical price and small space occupation.

Contact use for your own organic fertilizer making system immediately!

Screening

Screening for better granulation. On the one hand, it can screen out required fertilizer granules to next process. On the other hand, it can also sieve out unqualified particles and re-granulate. Screening is a way to avoid material waste and produce a more uniform fertilizer.

Dryer and cooler

Fertilizer dryer and cooler can help you reduce the moisture content of final swine manure organic fertilizer to 10%. In this way, you can package them to sell immediately. And the fertilizer can be storaged for a longer time.

Packing machine

Shunxin automatic packaging machine does not require manual operation, automatic weighing, and accurate measurement.

How to compost swine fertilizer quickly?

In the process of pig poop to fertilizer, composting is necessary. It is the key to eliminate harmful substances in manure, such as pathogens, pest eggs and grass seeds. Then is there method to speed up the aerobic fermentation of piggery farm waste? Of course. You can consider it from following aspects:

Prepare materials and add bacteria

First, suitable manure material is important. Fresh pig manure is usually better than old swine manure. So, during old swine manure management by composting, it is advisable to blend fresh piggery poop in the old. In addition, you can add fermentation bacteria or agent to speed up your swine manure compost manufacturing. Generally. It is enough to add 0.25 kg of pig manure starter to 1 ton of pig manure. Moreover, you can mix pig manure starter with rice bran or corn flour at a ratio of 1:5~10 for later use.

Remove excessive water from swine waste

When compost pig manure, the best moisture content is between 40%-65%. Less water, slow fermentation; more water, poor ventilation and slow composting. Too much moisture can also cause “spoilage bacteria” to work, which can lead to bad smells. Therefore, it is necessary to grasp the moisture content. Here, professional manure dehydrator can help you a lot. Quickly dry pig poop to the water content of 30%.

Build heaps of pig manure

Then transporting dried pig manure to fermentation area. You can choose to put into fermentation tank or pile into long windrow heaps according to your actual conditions. The height and width of the stack should not be too small, preferably 1.5-2 meters high, 2 meters wide, and unlimited in length.

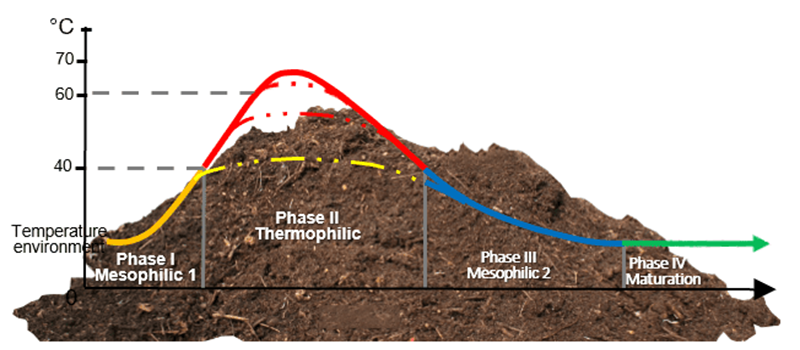

Control the temperature of swine waste compost making

During the fermentation of pig dung, high temperature is essential. When it reach to 60°C, it can kill harmful substances in manure. But it can not increase to 70°C, which will eliminate beneficial bacteria. In general, when the temperature no longer rise, the swine manure compost fertilizer is completed.

Turning and ventilate

Pig manure fermentation requires aerobic fermentation. Therefore, you need to supply oxygen timely in the pig manure decomposition operation. It is advisable to mix well, turn over and ventilate. Otherwise, it will cause anaerobic fermentation and produce odor, which will affect the fertilizer effect. At this time, it is necessary to use certain turning and throwing machines, such as groove type compost turner and windrow compost turner.

What Organic Fertilizer Production Lines for Your pig manure fertilier making?

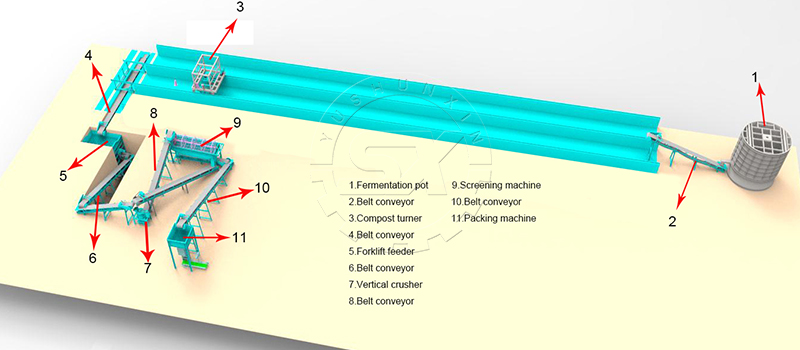

Powdery pig manure organic fertilizer production line – low cost

If you need a simple and low cost swine manure management plan, powdery organic fertilizer making system is an ideal choice. It only needs composter, loader type feeder, crusher, screen and packaging equipment to complete production. In addition, it can fully meet your requirement of 1-20 t/h pig manure fertilizer output. A complete minimum powder swine manure fertilizer production system only needs $10,000 – $30,000.

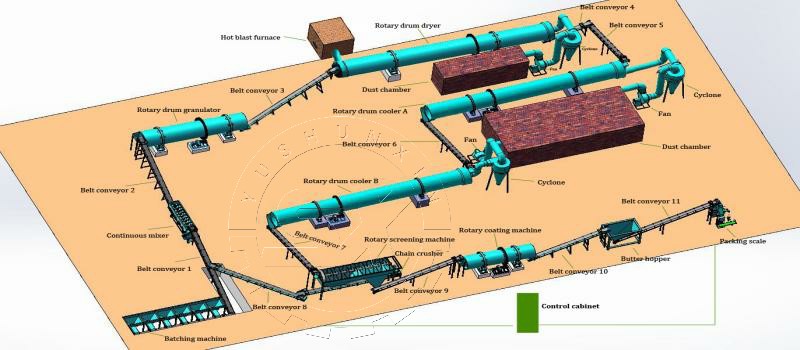

Swine manure waste to organic fertilizer pellets plan – Making more profits

When you plan to make pig manure into organic fertilizer granules, besides the above fertilizer machines, you alos need to buy mixer, granulator, dryer, cooler, pellet screener, etc. According to your capacity, budget, area, final pellet size and shape, we design various organic fertilizer granulators for your choice. Disc granulator, drum pelletizer, double roller extrusion machine, etc.

Top 3 Factors That Affect The Price of Pig Manure Disposal Machine

The output of the equipment

In general, the less the pig manure disposal volume, the smaller the output fertilizer requirement needed, the lower the investment. Adversely, the larger scale swine manure to fertilizer, the higher the budget. But, only tell us your actual conditions and requirement in details, we can offer you a customized project plan according your budget – the best solution for swine manure management.

Pig manure fertilizer making machine configuration

With simpler process of turning pig poop into fertilizer, you need to prepare lower budget for equipment. Here, we usually offer 3 types pig manure fertilizer making systems for your choice. Simplest powdery organic fertilizer making system, basic manure fertilizer granulation line and the above complete pig manure fertilizer manufacturing designs. You can choose the best one accoding to your budget.

Swine fertilizer equipment Manufacturer

Manufacturers will cause price differences. Generally speaking, powerful large manufacturers are more standardized when manufacturing equipment. In order to build a good user reputation for our own company, we are often cautious when selecting raw materials, and the quality of raw materials will be screened to a certain extent. The produced pig manure turning machine has better quality, low failure rate and good use effect. But the price is often a little more expensive than some small factories, because in order to reduce costs and increase competitiveness, small manufacturers are likely to have defects in raw material costs.

Why Choose Shunxin’s Organic Fertilizer Equipment?

Rich experience and good quality

Shunxin Engineering Equipment has been built for more than 20 years and has rich experience and technology. With a large number of engineering and technical personnel and lathe production equipment, large green production plants, independent and complete production processes, it can meet the production of various parts and components. Factory equipment is repeatedly inspected and tested to ensure quality. Only after passing the quality system certification can it be sent to the user, and the use is more assured.

2. Perfect and reliable service

Shunxin’s organic fertilizer equipment is of good quality and service is more secure. From pre-sale, in-sale and after-sale services to users, effectively solve various production problems of users. Any questions can be asked. If there is a problem during use, the sales staff will answer patiently and carefully and provide solutions within 24 hours. All kinds of accessories are ready at any time to satisfy every user.

What is the Profit of the Pig Manure Organic Fertilizer Production Line?

In our country, the price of fresh pig manure is only 80 to 100 yuan per ton. But the price of powdered organic fertilizer is 300-400 yuan per ton, and the price of granular organic fertilizer is 400-700 yuan per ton. The construction cost of the plant is about 1,500 square meters for an organic fertilizer production line with an annual output of 10,000 tons, and the construction cost per square meter is 300-500 yuan. The profit per ton of finished pig manure organic fertilizer is about 150-200, and the total annual profit is 1.5-2 million.