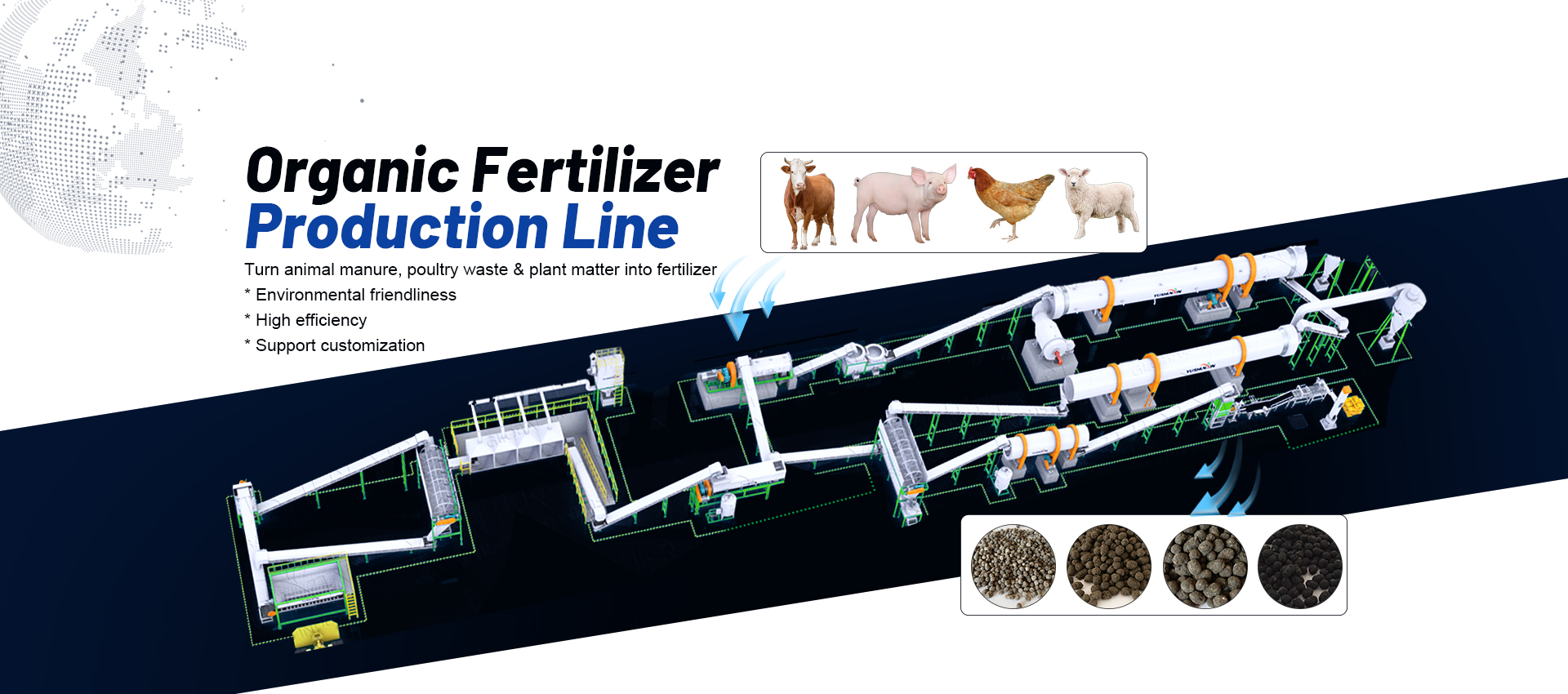

In order to fully meet your requirements for organic fertilizer production, we especially design various business plans for your choice. Whether you want to use chicken poop, goat manure or cow dung as material, in a small or large scale, high or low investment, etc, you must find the best solution for your organic fertilizer making plant setup. In 2023, there were 3 types of organic fertilizer production projects that are best-selling. They have won good feedback from many organic fertilizer manufacturers at home and abroad.

Organic Fertilizer Making System

- Capacity: 1-20 t/h

- Area: 800-10,000 ㎡

- Equipment material: Carbon steel Q235/Alloy

- Voltage: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Types: Composting sytem, granulation system, drying system, etc

- Application: Dispose of chicken poop, cow dung, goat manure, straw, biogas redsidues, sludge, etc

Contact use for your own organic fertilizer making system immediately!

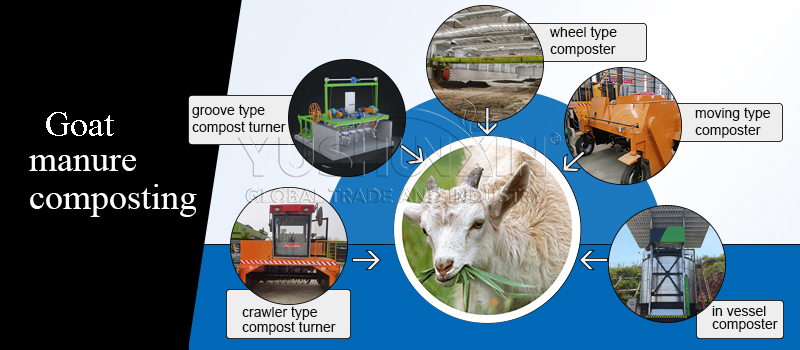

Top 1: fertilizer composting system of goat manure

When you plan to use goat manure as fertilizer, it is necessary to remove harmful substances in materials. This harmless process of goat waste is composting – aerobic fermentation. Here, we can offer you professional mechanical goat manure compost system. It mainly consists of dehydrator, compost machine, crusher and packaging machine. Its output range is from 1 t/h to 20 t/h. And the price of the fertilizer compost system is only $ 5,000-$80,000. Large capacity and low investment. Therefore, it is very popular with those who needs an economical farm manure management plan.

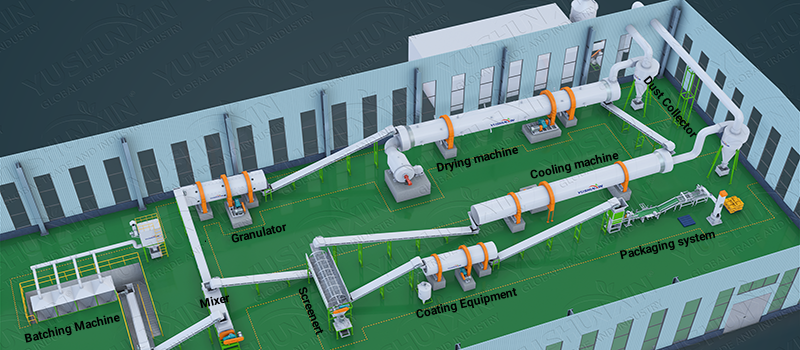

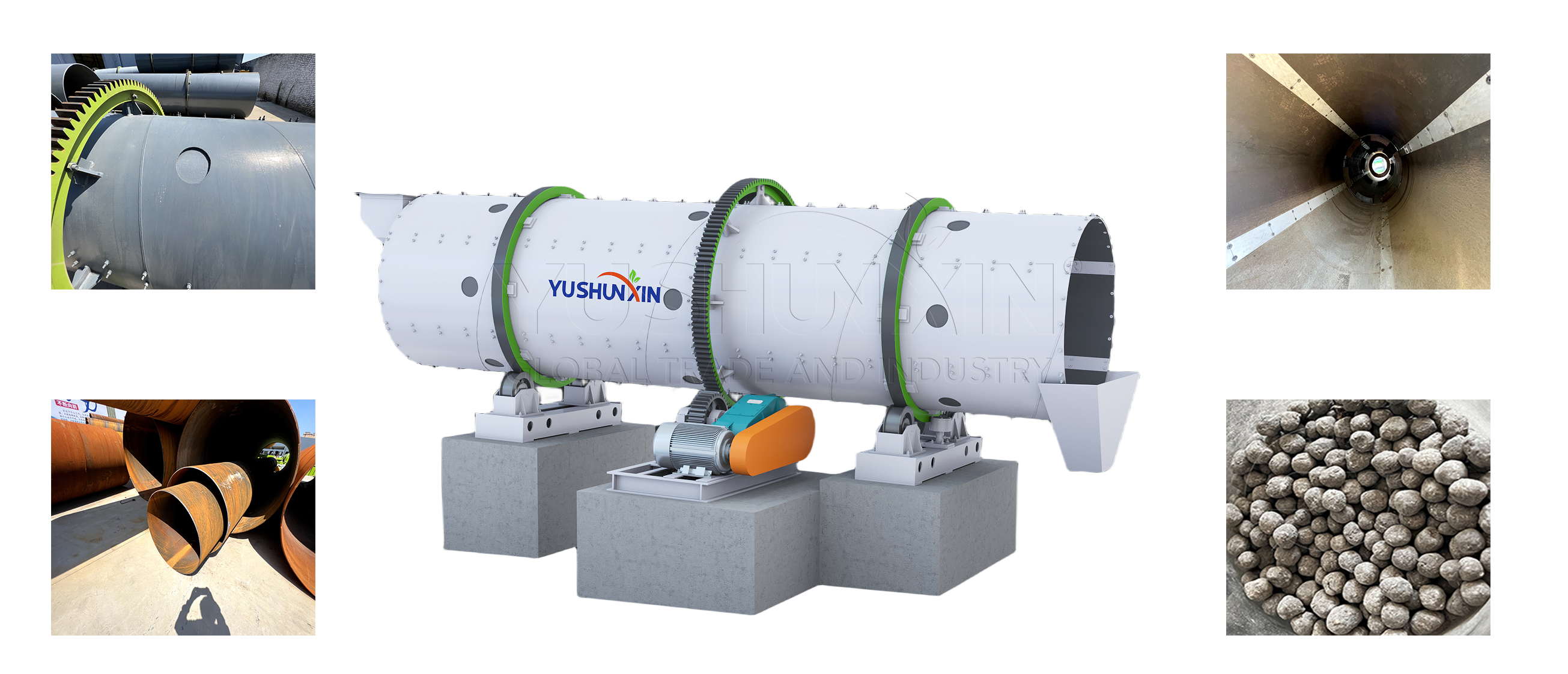

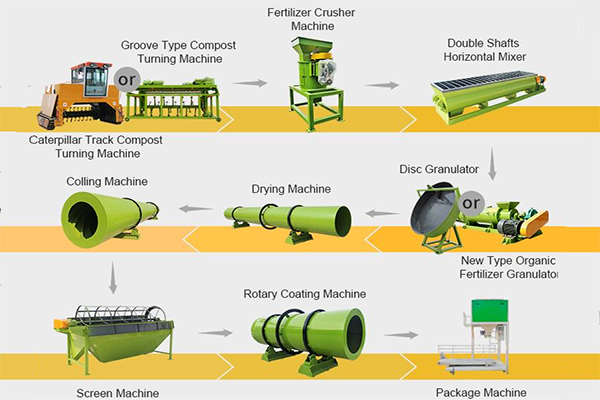

Top2: fertilizer rotary granulation system

However, from the feedback of our past customers, when making organic fertilizer granules, rotary drum granulation line is the best choice. The organic fertilizer project is suitable for not only small scale organic pellets making but also large scale manure to fertilizer granules. From 1 t/h to 30 t/h, it only uses a set of fertilizer granulator. Moreover, it can prepare granular fertilizer from various materials. Such as chicken poop, cow dung, goat manure, pig waste, etc. And even NPK pellets manufacturing. So, the rotary drum granulation system is the best choice for industrial fertilizer production plants.

Get more details about rotary drum granulation system !

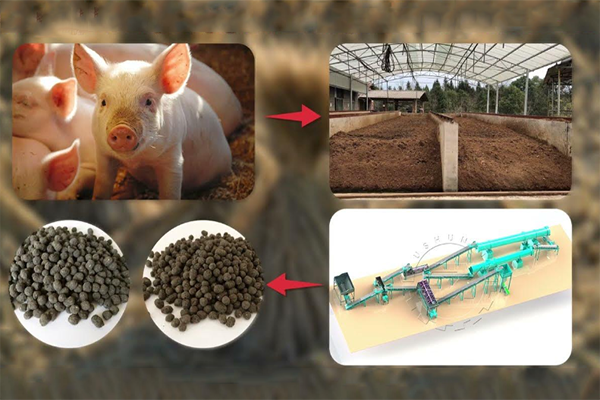

Top 3: Swine manure management project

This project is designed for farmers who need an environmental and fast pig farm waste disposal method. It contains pig manure drying system, pig poop composting line, organic powder fertilizer system, swine manure granulation process, packaging and dust collection devices. You can choose them according to your actual conditions. Capacity, area, budget and others. Whether you have a small or large swine farm need to dispose of pig manure waste or plan to start organic fertilizer making business by using pig manure, you get the best solution.

The above is the top 3 hot sale organic fertilizer production projects in YUSHUNXIN in 2023. And except for them, there are many other high quality fertilizer processing lines on sale. For example, chicken manure management system, bio organic fertilizer production line, compound fertilizer making line, etc. If you are interested in them, please contact us. We will provide you with high quality fertilizer processing machines at a favourable price!

Error: Contact form not found.