Manure is a natural source of plant nutrients, but make no mistake, it has to be transformed to be effective as a soil conditioner. Planned application of organic fertilizers can make your soil active and better provide nutrients for plants. Under the NOP, “farmers and food processors who wish to use the word organic in reference to their businesses and products, must be certified organic.” When you are looking for an organic source for your plants, organic fertilizers are the most straightforward choice . The National Organic Program has established some standards for the conversion of manure into organic fertilizers to avoid damage to crops such as excessive nutrients and pathogens. So how to dispose of your animal waste organically? Setup a organic manure production plant to compost farm manure waste and convert compost to powdery or granular organic fertilizer according to your needs.

How to Use Manure as Fertilizer?

Composting your poultry manure or livestock manure

Find the right compost location

The location should be away from drainage areas and nearby residential areas, and secondly, close to your crop or farm. On the one hand, it can shorten your raw material transportation distance, on the other hand, it can reduce the impact of raw material accumulation on nearby residents.

Choose the correct composting method

You can consider trench compost making or window composting for your organic manure production plant. Trench type composting is suitable for fertilizer producers with a large amount of manure. While windrow compost is suitable for small fertilizer producers or composters.

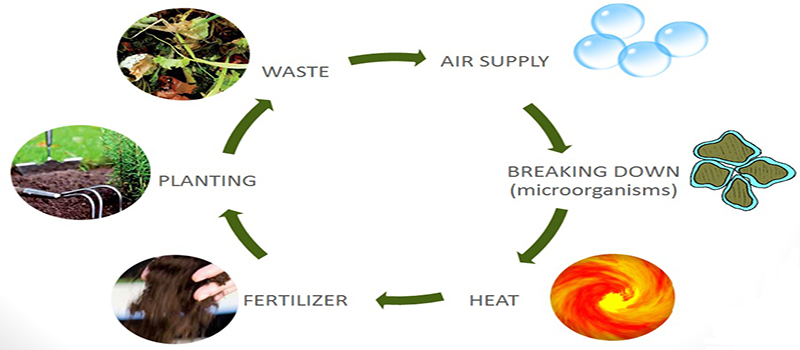

Turn your compost regularly.

Composting is the process by which microorganisms decompose organic matter. During this process, you need to provide oxygen to your pile by turning it. On the other hand, microorganisms generate heat through their activities to kill harmful germs and weed seeds etc. in the feces.

Processing your manure as organic fertilizer

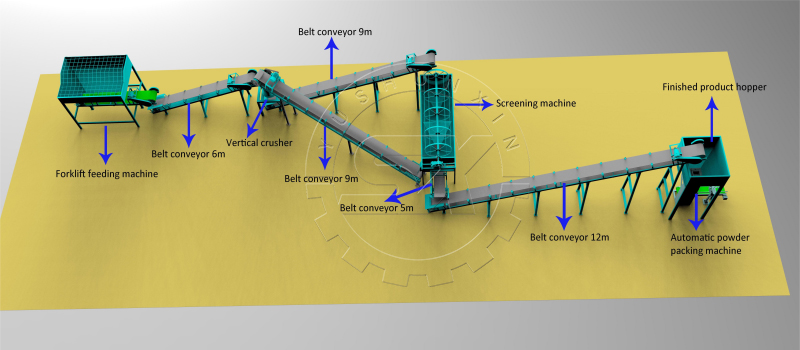

In the production stage of treating manure into organic fertilizer, you need some machines to help you complete the granulation of fertilizer. What needs to be known is that organic fertilizers are mainly divided into two types: powdered organic fertilizers and granular organic fertilizers. So first you need to consider which form of organic fertilizer to produce.

Powder organic fertilizer making process

Generally speaking, the production cost of powdered organic fertilizer is relatively lower. Because it does not require granulation equipment, some simple processes can produce powdered fertilizers. Only including compost machine, batching equipment, crusher, screener and packaging machine.

Organic fertilizer granule production

If you want to produce granulated organic fertilizer, the choice of granulator is very important. The organic fertilizer granulator mainly adopts wet granulation method, such as disc granulator, stirring tooth granulator and drum granulator. In these machines, your fermented manure will be pelleted into spherical pellets, which store nutrients in the manure.

What is the process of organic manure production plant?

Organic fertilizer raw material processing

Almost all manure can be used as compost material for organic manure. But among these manures, some manures have a moisture content as high as 90%. Before composting, you need to reduce the moisture content in these manures. First, you can add some agricultural waste such as straw, corn stalks, wood chips, bagasse, etc. Or you can choose to buy a dehydrator for solid-liquid separation.

Raw material composting

Windrow compost is a common method of composting in most areas. Composting in this method can be done in long strips of compost. You need to pile your compost material into long strips 1-2 meters high. Then select the window compost turner and turn the compost once every two to three days.

Compost crushing

The composted material particles are too coarse and have agglomeration phenomenon. Therefore, your material needs to be crushed into fine powder before granulation, so as to better granulate

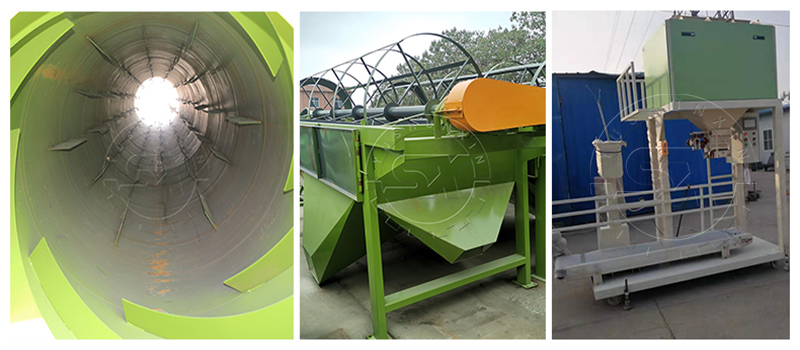

Organic fertilizer granulation

Choose a suitable granulator to give you fine powder particles for granulation. Granulation not only preserves the nutrients in manure, but also improves the efficiency of fertilizer storage. Due to its high granulation rate, our new organic fertilizer granulator has been sold to the United States, Myanmar, Indonesia, Philippines, Malaysia, South Africa, Spain and other countries. Also, the disc granulator becomes one of our top selling granulators in 2022. The drum granulator becomes the granulator with the highest production capacity. These three granulators can be used for granulating organic fertilizers.

Drying and Cooling Process

The finished granular organic fertilizer contains a certain amount of water, and more water will affect the transportation and fertilizer efficiency of the fertilizer. Therefore, the drying procedure is an important process in organic fertilizer processing. The rotary dryer uses a hot air oven to rotate the pellets in a drum to air dry and remove moisture. A cooler is used to reduce the temperature of the dried pellets.

Screening

Before bagging or bulking, organic fertilizer granules should be screened to obtain the desired particle size and remove unqualified product granules. In this process, fertilizers are separated by screening into products that can be used as fertilizers. The waste re-enters the granulator for granulation.

Package

The finished product granules are transported to the automatic packaging machine by the belt conveyor for packaging.

How much quantity manure is required to start a commercial organic fertilizer project (small or medium)

For a small manure organic fertilizer plant, you have a source of below 300 tons manure per day, you can consider building a small manure organic fertilizer plant. But if you have more than 300 tons of poultry manure per day, then you can consider a business plan for an large scale organic fertilizer plant. A large organic fertilizer plant will bring you more commercial benefits.

Error: Contact form not found.