During the organic fertilizer production, there must be some questions you have for SEEC fertilizer machines. Here are some frequently asked questions from our customers. Whether you want to get the solutions for your fertilizer making plant or know the details of our machines, we can provide you professional suggestions and answers.

Dewatering Process

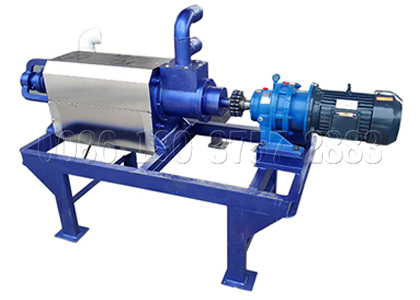

Q: What is the requirement of moisture content for your dewatering machine?

A: It can process the materials, whose moisture content is above 50%. And after dewatering, the moisture content will be lowered to about 30%.

Q: May I use the separated liquid as fertilizers directly after dewatering?

A: I am not sure. But on my opinion, I think it is not suitable to use it directly. Because the fresh animal waste has too much unhealthy bacteria, and they will hurt the seedling.

Q: After the dewatering, how should I process the dewatered manure into available organic fertilizers?

A: For your organic manure fertilizer making, we recommends you manure composting machine for turning them into available fertilizers. With a compost making machine, you can get high-quality organic manure fertilizers in a short time. And it is also alternative for you to make them into finer powdery or granular fertilizers, we have complete fertilizer machines for you to process.

Fermentation Process

Q: How many days does it need for finishing the whole fermentation process?

A: Using different compost machines, the time will be different, too. Generally, if you use our compost turner machine for composting, it will take you about 20 days for the whole composting. And for your large scale organic waste fermentation, our fermentation tank will be helpful. Especially, you can get well-fermented manure fertilizers in only a week.

Q: After composting, can I get available fine organic fertilizer powder?

A: Generally, using our compost machine for fermentation, the finished organic manure will be powdery. But there will be some blocks. Thus, for your commercial organic fertilizer powder making, you can equip with our fertilizer crushing machine for fine powder pulverizing.

Crushing Process

Q: Will the fermented manure blocks your semi-wet materials pulverizing machine because of the high moisture content of manure materials?

A: Our semi-wet materials crushing machine is often used for pulverizing fermented materials. It can process materials, whose moisture content is between 20%-40%.

Granulating Process

Q: What is the main principle of your fertilizer granulating machine for manufacturing organic manure?

A: Our organic fertilizer granulators uses wet granulation for pelletizing. It can process your materials, whose moisture content is about 30%-40%.

Q: If the moisture content of materials is lower than 30%, can it granulate?

A: Generally, the moisture content of materials should be 30%-40% for granulating. If the moisture content is lower, the granulation effects will be not so good. It is suitable for spraying water when processing.

Q: After granulating, what is the moisture content of pelleted fertilizers? Will it be below 10%?

A: No, it can not be below 10%. Generally, after granulating, the granules will be about 20%. You can use a rotary drying machine to lower the moisture content.

Q: How should I control the size of granular fertilizer? If the fertilizer granules are too big, how can I make them smaller?

A: There are two ways for you to control the size. You can control the moisture content or pan slope angle for changing the sizes of pelleted fertilizers. The much the water, the bigger the granules. As for the slope angle, the slow the slope, the bigger the size of fertilizer pellets.

Q:How long it will take for turning powder into pellets when granulating?

A: About 5-8 minutes usually.

Q: Can you make closed pan type granulator so that there will be less dust generation?

A: If you want to reduce the dust generation, you can cover the granulator by iron sheet house. And the closed pan type granulator design can not be realized. Because if the pan granulator is closed, it is not applicable for you to feed materials into the machine.

Q: What is the advantages if I use the organic fertilizer dedicated granulation machine?

A: This machine is designed for manufacturing organic fertilizer granules dedicatedly. Using this granulator, the granules will be harder than fertilizer pellets made by rotary drum granulator or pan granulation machine. Meanwhile, the granulation rate is the highest among all the granulators.

Screening Process

Q: When should I use the rotary screening machine?

A: You can use this machine in 3 phases. Before the fermentation, after crushing and granulating.

Before the fermentation, there may be some finger stone, etc., the screening machine can select them out. And after the crushing, you can use the fertilizer screener machine for classifying the fine powder and unqualified powder for better fertilizer effects. Besides, for your fertilizer granules manufacturing, this machine is often used for classifying the qualified and unqualified fertilizer granules after the granulating.

Error: Contact form not found.