A complete chicken manure organic fertilizer production line is mainly composed of two parts: fermentation and granulation. It is precisely because these two parts affect the overall price of the organic fertilizer production equipment sales industry. For example, the daily production of chicken manure in small and micro chicken farms is not much. At this time, as an organic fertilizer production equipment manufacturer, it is recommended that users only purchase the compost turner separately. In this way, farmers only need to invest a small amount of money to meet the needs of harmless treatment of chicken manure.

For slightly larger small and medium-sized chicken farms, Shunxin and experienced technicians will customize organic fertilizer equipment according to user needs. This is because factors such as different chicken manure treatment volumes, different feeding methods, different surrounding environments, and different budgets made by customers directly affect the specific configuration and cost of a complete set of chicken manure organic fertilizer production equipment. Next, Shunxin takes the production of commercial chicken manure organic fertilizer as an example. In simple terms, it can be summarized into the following three common configurations.

Wheel Type Composting Equipment

Turning depth: 1.5-3m

Turning span:≤3om

Advantages: Highly automatic, energy-saving

Color: red(can be customized)

Application: composting organic wastes to fertilizer

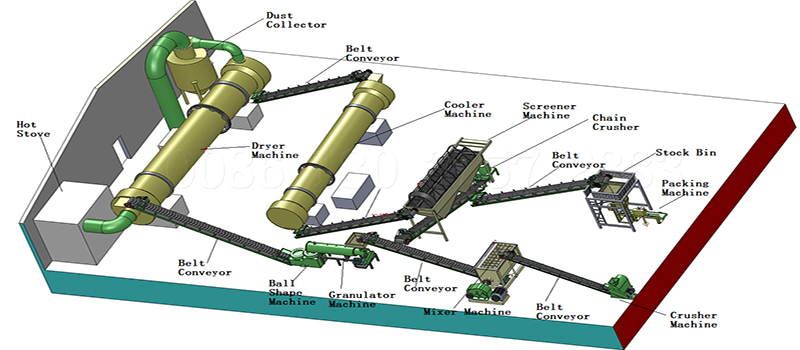

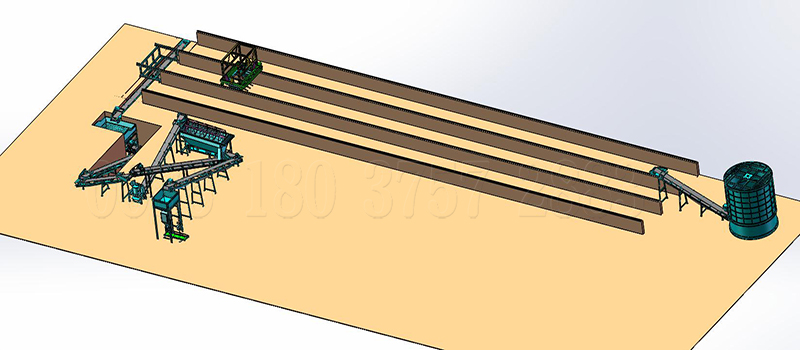

Complete production line: pre-fermentation part (chicken manure dehydrator, fermentation turning machine); post-granulation part (semi-wet material crusher, horizontal mixer, organic fertilizer granulator, dryer, cooler, drum) Screening machine, coating machine, packaging machine equipment, belt conveyor, etc.).

General production line: pre-fermentation part (manual self-processing); post-granulation part (semi-wet material crusher, horizontal mixer, organic fertilizer granulator, dryer, cooler, drum screening machine, packaging machine equipment , belt conveyor, etc.).

Simple production line: pre-fermentation part (manual self-processing); post-granulation part (semi-wet material crusher, horizontal mixer, granulator/drum screening machine, packaging machine equipment).

For private small chicken farms, if the problem of sales channels can be solved, for example, local and peripheral sales. Equipment configurations that do not use the above commercial organic fertilizers are possible. You only need to buy a fermentation compost turning machine with suitable processing capacity; if you need to add organic materials such as straw, vegetation, medicinal residues, etc. during the fermentation of chicken manure composting, then buy a crusher; if you want to make the fermented chicken manure organic fertilizer If the appearance is better, you can buy another drum screening machine.

Through this method of purchasing organic fertilizer production equipment with more refunds and less compensation, the purchase cost of small-scale chicken manure organic fertilizer production equipment can be greatly reduced. It can also meet the needs of harmless treatment of chicken manure. Because it is sold nearby, the fermented chicken manure organic fertilizer does not need to be granulated, which saves the investment in purchasing granulator equipment.

How much does a small chicken manure organic fertilizer production equipment cost? Because the organic fertilizer production equipment used in different situations is different, the price range for each increase or decrease of a piece of equipment varies greatly. Shunxin recommends that you send an email to consult us!

Error: Contact form not found.