For an organic fertilizer plant setup, cost is an item you must pay attention to. then how to start an organic fertilizer factory at lowest price? in general, you can consider it from the following 4 aspects:

Consider the source of raw materials for organic fertilizers

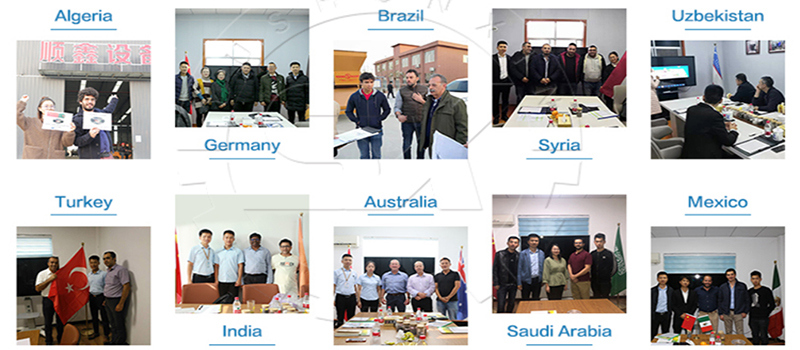

The raw materials of organic fertilizers are rich and varied. Common sources of organic fertilizer raw materials are chicken manure, pig manure, cow manure and other livestock manure. In fact, in addition, sludge, agricultural waste, kitchen waste, biogas residue, cake residue, etc are also excellent sources of organic fertilizers making. They are rich in nitrogen, phosphorus, potassium, etc. For example, in 2020, a customer from Algeria, his raw materials are biogas residue, rice husk and cassava residue. We ended up recommending the wet granulator to him because these materials have a high moisture content. So first you need to determine the raw material of your organic fertilizer. Of course it is best if you own a poultry or livestock farm. You don’t need to worry about the source of raw materials.

Understand the production process of organic fertilizer

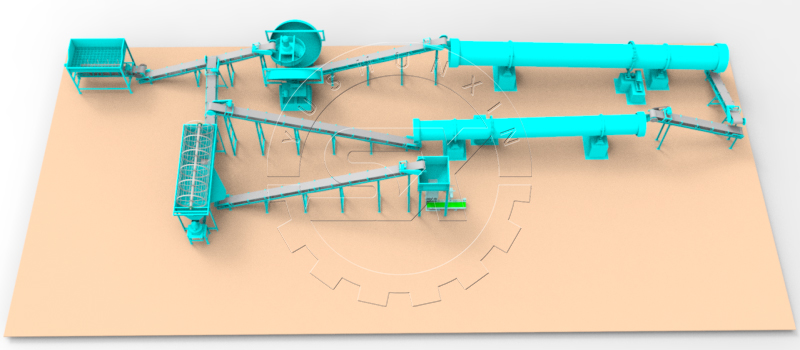

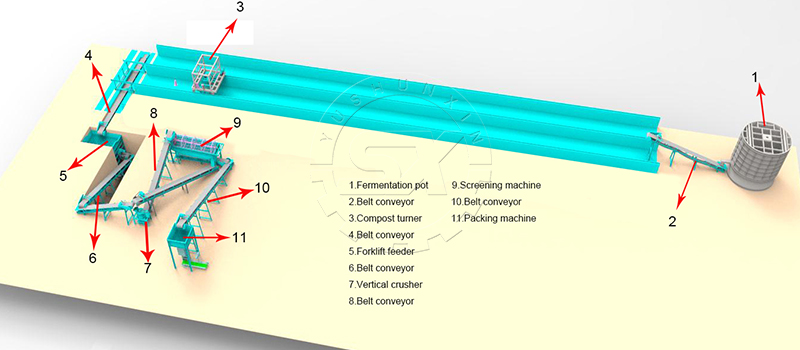

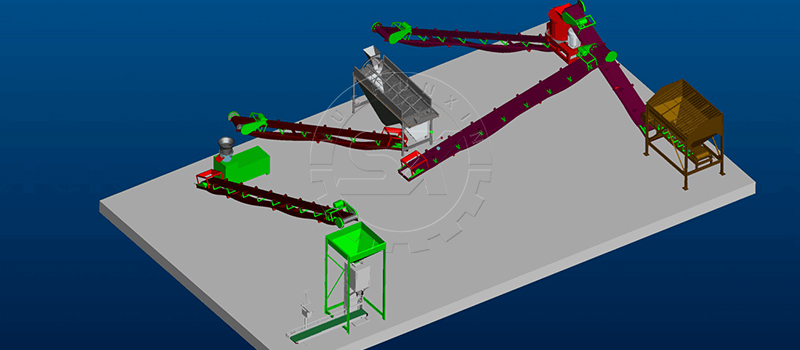

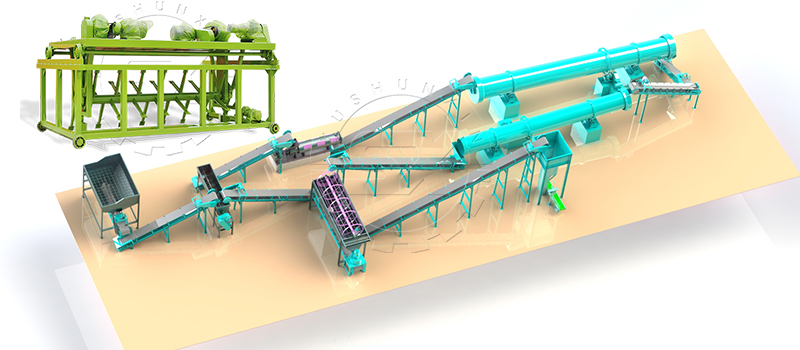

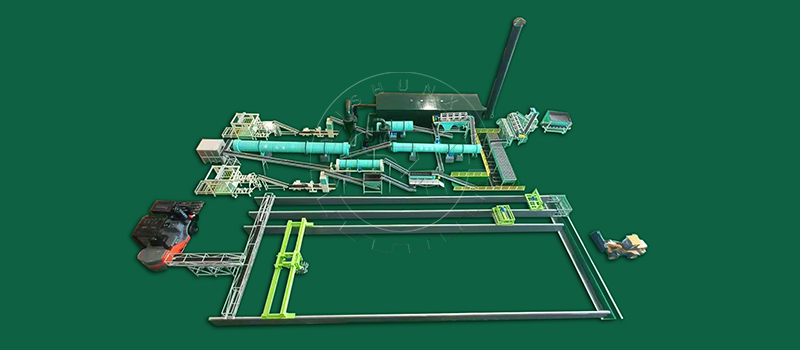

First, you need to decide whether you want to produce powdered organic fertilizer or granular organic fertilizer. In fact, granular organic fertilizers are more dominant in terms of nutrients and storage. However, there are also more production procedures for granular organic fertilizers. The complete production process of granular organic fertilizer is compost fermentation – crushing – screening – batching – stirring – granulation – drying and cooling – packaging. This may seem complicated, but you can choose according to your needs. Or you can contact for the best solutions. As a fertilizer equipment supplier with more than 20 years of experience, Shunxin has helped solve the fertilizer production problems of many customers in China and abroad.

Determine the production scale of your factory

Company size is one of the factors that affects output and cost profit. If your capital investment is larger, then your income will be larger. For 1-3 t/h organic fertilizer pellets making, you can choose plat die granulation line. For 1-10 t/h organic fertilizer plant setup, both disc granulation line and new type granulation system can fully meet your needs. However, if you want to further enlarge your organic fertilizer factory scale, rotary drum pellet line is the best choice. It can finish the large scale organic fertilizer granule making quickly and reduce your cost.

Contact use for your own organic fertilizer making system immediately!

Determine the organic fertilizer production equipment

When you have some organic fertilizer raw materials, you may not know how to choose the right production equipment. Or you may not know how to maximize your benefits. Starting your organic fertilizer production business is not an easy task. What you need to remember is that you should communicate with professionals to help your organic fertilizer production business. Your ingredients, your venue, and your budget will all affect your bottom line. Shunxin has professional consultants and engineers. If you have any questions, our professionals will give enthusiastic answers. We can even help you design the venue, cost, etc. So if you don’t know how to get started, please email us!

Error: Contact form not found.