In general, the profitability of organic fertilizer production line is closely related to two aspects. Cost and earning. Then the key factors for organic fertilizer production line cost and earning are as follows:

Determine the scale of the organic fertilizer production line

Such as how many tons per year, or how many tons per hour. In general, the smaller the capacity, the lower the investment and the lower the earning. The larger the capacity, the larger the expense and the higher the earning.

Determine the shape of fertilizer in the organic fertilizer production line

Organic fertilizer production lines consist of two categories, one is powdery organic fertilizer production line, and the other is granular organic fertilizer production line. Generally, producing granular organic fertilizer can make more profits than making powdery organic fertilizer.

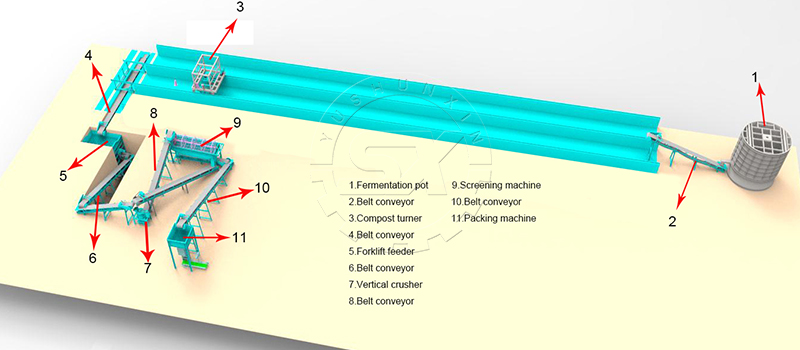

Determine the configuration of the organic fertilizer production line

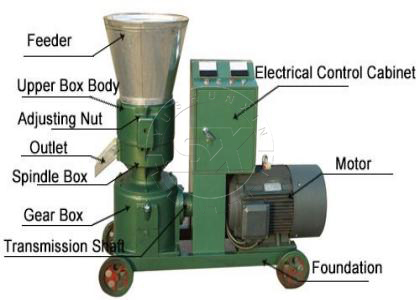

The equipment configuration of the organic fertilizer production equipment is different, and the price is different. For example, powdery organic fertilizer includes fermentation turning equipment, crusher equipment, and organic fertilizer screening equipment. The price of whole set equipment is only around tens of thousands of dollars. But for organic fertilizer pellets making, besides the above basic equipment, automatic batching equipment, automatic packaging equipment, automatic quantitative feeding equipment, cyclone dust collector, solid-liquid separation equipment, etc. also need.

Moreover, different types of fertilizer equipment have different prices. Commonly used organic fertilizer granulator equipment includes: disc granulator, drum granulator, double roller extrusion granulator, flat die granulator, and tooth-stirring granulator. If you need a low cost organic fertilizer granulator, disc granulator, plat die pelletizer and double roller granulator are better choices for you. Then you can choose the most suitable one according to your actural conditions and requirements.

Determine the type of organic fertilizer production

Compound organic fertilizer production line or organic fertilizer production line has the same output. Organic fertilizer production line generally considers high moisture content, beneficial bacteria are not resistant to high temperature, and the model is larger than the compound fertilizer model. There are four types of organic fertilizers: pure organic fertilizers, organic-inorganic compound fertilizers, bio-organic fertilizers, and compound microbial fertilizers. The configuration of organic fertilizers is also slightly different. So the costs of them are different.

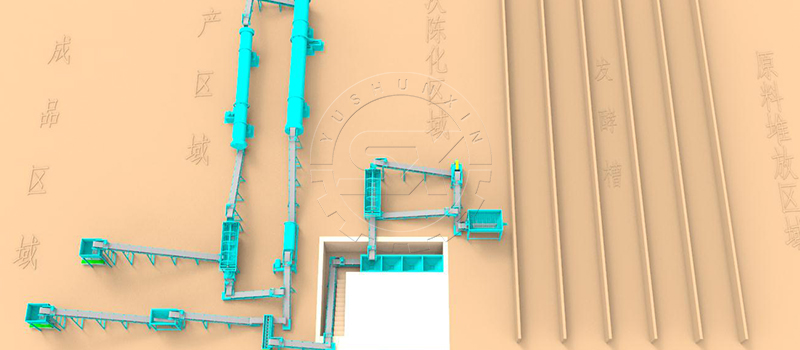

Selection of organic fertilizer fermentation turning machine

Common organic fertilizer fermentation methods include in-vessel fermentation, trench composting and windrow composting. Compared with windrow compost method, you need to build fermentation trenches when your plan to start aerobic fermentation of organic fertilizer in grooves.

Determine the environmental assessment to be achieved

In areas with low environmental assessment requirements, you can select ordinary dust removal equipment, and the investment in organic fertilizer production lines is low. Areas with high environmental protection requirements need to use high-performance dust removal equipment, and the equipment has a good effect. It can fully meet the environmental protection standards required by the state, so the investment will be higher.

Error: Contact form not found.