Last week, our newly published page about the NPK production line caught the attention of a buyer in Maseru. When the buyer searched for information on NPK granulation plants on Google, he saw the design plan of the NPK fertilizer production line on our website. He was so interested that he contacted us via email. The customer was very impressed with our NPK production line, and he expressed that he wanted us to design a 100 t/d NPK fertilizer production line for him.

What do Our Customers Want?

In the email, our customer mentioned ”We need to produce NPK fertilizer. We need full automatic production line and our daily capacity 100 ton. Our granule must to be round pellet and pellet size between 2- 5 mm diameter.” I hope we can provide a fully automated NPK production line with a production capacity of 100 t/d. The NPK fertilizer particles produced by the customer must be between 2-5 mm. The customer’s requirements are very clear.

The customer mentioned in the email that their raw material is urea or ammonium sulphate for nitrogen , diamonium phosphate for phosphate and potassium sulphate or photasium chloride for potassium. As an international manufacturer of fertilizer equipment, we provide various types of NPK fertilizer granulation machines and production lines.

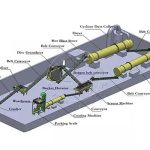

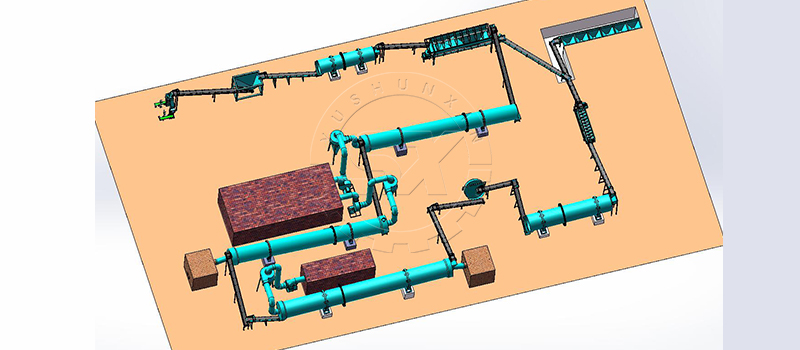

8-15 t/h Rotary Drum NPK Fertilizer Production Design Project

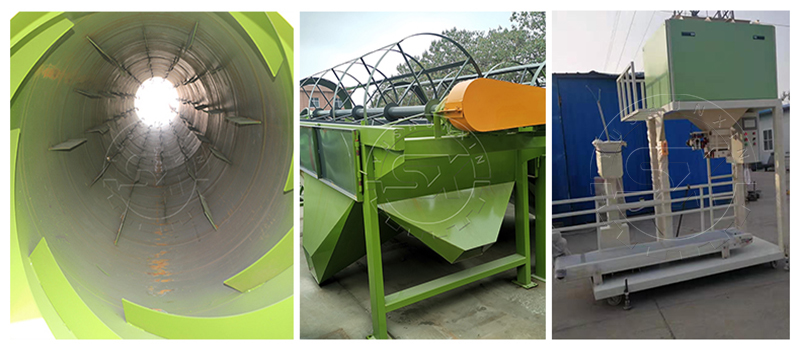

Considering the requirements of 100 t/d NPK fertilizer production line from our customers, we recommend our SXZGZ-2080 drum granulator to our customers. The length of this granulator is 8000 mm and the diameter is 2000 mm. It has a production capacity of between 8-15 T/h. 7-8 hours of production per day can meet the customer’s production requirements of 100 t/d. Due to its large production capacity, the drum granulator is more suitable for the production of NPK fertilizers. Its granulation method iswet granulation method. Through a certain amount of water or water vapor, NPK powder can quickly condense into agglomerates under the high speed operation of the drum.

Why Choose a Drum Granulator?

- The drum granulator can meet the requirements of customers in terms of output. The maximum production capacity of our drum granulator can reach 30t/h.

- The drum granulator has a higher granulation rate. One of the reasons why many customers choose drum granulator is its high granulation rate. Through the humidification of water vapor, and under the high-speed physical force, it can be quickly granulated.

- Cleaning system. There are many circle-shaped holes on the wall of the drum granulator, and there are small hammers on these holes. With the rotation of the cylinder wall, the small hammer will naturally hit the round hole, which can prevent the material from sticking.

- Anti-corrosion lining. On the inside of the barrel, we have designed a rubber lining for the drum granulator. On the one hand, it prevents the adhesion of the material, and on the other hand, it prevents the material from eroding the wall of the cylinder.

A Complete 8-15 t/h Rotary Drum NPK Fertilizer Production Line

Although there is an efficient drum granulator, a complete NPK production line also needs other auxiliary equipment. This complete production line also includes batching machines, screening machines, drying machines, cooling machines and packaging machines, etc. We sent the drawing of this complete production line to the customer. And informed the customer of the production process of the entire production line.

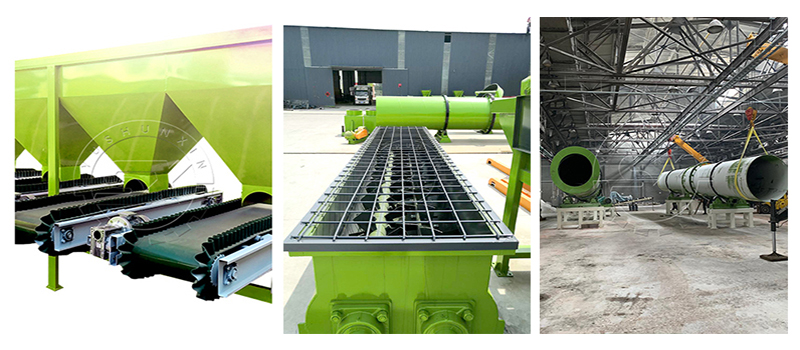

Four warehouse dynamic batching machine.

According to the customer’s raw materials, we designed a dynamic batching machine with four warehouses for him. The amount of each ingredient is precisely quantified.

Double-shaft horizontal mixer

The function of the mixer is to mix a variety of materials evenly to ensure the production of NPK granules with balanced quality and nutrition.

Rotary dryer

The dryer can reduce the moisture content in the granules, and the moisture content of the granules after drying is about 10%.

Cooling machine

The dried NPK particles cannot be granulated directly because the temperature is too high. It can be packaged after cooling down.

Screening machine

The screening machine can screen out the qualified particles for the next packaging process. Of course, the screening machine will also screen out unqualified particles and continue to return to granulation.

Automatic packing machine

The packaging machine automatically packs a certain weight of NPK granules. No need for manual weighing, high precision.

Error: Contact form not found.