For sheep manure to fertilizer, most fertilizer manufacturers choose to make sheep manure materials into organic fertilizer granules. Why? Because it greatly beneficial for easier transport, storage and use. Then how to start sheep manure organic fertilizer granules making? SX will offer you best solutions.

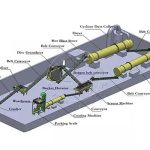

What is the process of sheep manure fertilizer granules making?

Pretreatment

All raw materials used for fermentation are processed to a particle size below 1-60 mm through crushing equipment, which is convenient for improving the contact surface of materials during fermentation.

Fermentation of Sheep manure

Raw material ratio, adjust the water content and the ratio of various raw materials. The adjustment of raw material ratio should meet the normal range of carbon-nitrogen ratio of about 30:1. The addition of other auxiliary materials should be combined with local market demand or soil testing. Then, turn material piles to start sheep manure composting, which can kill the harmful substances in manure waste.

Raw material crushing

The fermented raw material has been fully decomposed. But if you want to prepare sheep manure fertilizer pellets, you need to further grind it by semi-wet material crusher. The fine powder sheep waste materials makes fertilizer granulation easier.

Stirring of raw materials

If other auxiliary materials need to be added to the fermented raw materials according to the market demand, it is necessary to use a mixer for sufficient mixing, or some raw materials need to be added with auxiliary granulation materials to improve the success rate of raw material granulation.

Sheep manure fertilizer granulation

Using suitable organic fertilizer pellet making machines to turn processed sheep manure mixture into organic fertilizer granules you need.

Drying and cooling

The granulated material still contains about 30% moisture, use a rotary dryer to dry the moisture to below 15%, and then use a cooler to quickly cool down and shape, improve the strength of the granules, and facilitate transportation and storage.

Particle screening

The cooled particles are classified by a drum sieving machine, the oversized or undersized particles are crushed and re-granulated, and the qualified products are screened out and flowed into the next process.

Coating of finished products

Coating qualified products to increase the brightness and roundness of particles. Or enrich the sheep manure fertilizer nutrient and make slow-release organic fertilizer pellets.

Finished product packaging

The film-coated granules, that is, the finished product, are packed into bags by automatic packaging machine or manually according to the output and labor conditions, and transported to the finished product warehouse.

How to make sheep manure into compost?

When you plan to make organic fertilizer pellets from fermented sheep waste, you can process it with granulator directly. However, if you use fresh goat manure as organic fertilizer granules making material, it is advisable to compost it first.

Removing excessive water from sheep waste

Usually, fresh goat manure has a high moisture content, which is not suitable for the aerobic fermentation of raw material. Here, you need to reduce the water content to 45%-60%. For this, you can mix sheep manure with appropriate amount of straw powder or other materials with a low moisture content. Is there a fast method? Of course. You can process manure with professional dehydrator, which can make the moisture content decrease to 30%-40% in a short time.

Add auxiliary materials to speed up sheep poop compost making

In order to compost sheep manure quickly, you can The add biological compound bacteria into manure materials with proportion of 3 kg:1 ton (about 1.5 tons of fresh material). In this process, the dilute ratio of bacterial liquid and clean water is 1:300. Moreover, you also can add an appropriate amount of corn starch to provide sugar for the fermentation bacteria, so that the multidimensional compound enzyme bacteria will soon take the absolute advantage.

Processing manure compost piles with compost turner

Next, piling shepp manure mixture into strips with a width of 2.0 m-3.0 m and a height of 1.5 m-2.0 m. The fermentation effect is better for piles with a length of more than 3 m. Then turning it with professional industrial compost turner about every 3 days. Therefore, the temperature of compost piles can reach 60°C-70°C quickly, which can kill insect eggs and other harmful substances in organic waste. After 1-2 weeks, sheep poop piles temperature will no longer rise and you can get quality compost fertilizer.

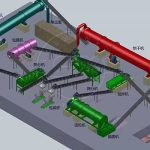

What equipment we can use to make compost into sheep manure fertilizer pellets?

If you want produce quality sheep manure organic fertilizer granules, a suitable fertilizer granulator is necessary. There are 3 types of manure pellet machines that are popular with fertilizer manufacturers. Stirring teeth granulator, disc pellet making machine and double roller extrusion pelletizer. You can choose the best one according you needs.

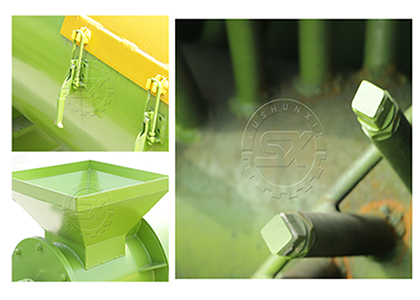

Stirring Teeth Granulator For high hardness organic fertilizer pellet preparation

When you want to make sheep manure compost into organic fertilizer granules with a high hardness, stirring teeth granulation you best choice. In general, its feeding material moisture content of 20%-40%.During granulating sheep waste materials, stirring teeth make use of the mechanical stirring force of high-speed rotation and the resulting aerodynamic force. It makes the fine powder material continuously realize the processes of mixing, granulation, spheroidization, and densification in the machine, so as to achieve the purpose of granulation.

And the production capacity is generally 1 to 8 tons per hour. The shape of the final organic fertilizer particles is spherical, the particle size is generally between 0.3-5 mm, and the ball forming rate is greater than 95%. The size of the particle diameter can be properly adjusted by the amount of material mixed and the spindle speed. Generally, the lower the mixing volume, the higher the speed, the smaller the particles, and vice versa.

economical Disc sheep manure fertilizer Granulator

Disc granulator is a mature organic fertilizer granulation equipment, which has the characteristics of simple structure, low cost and convenient maintenance. After proper processing, sheep waste compost is conveyed to the top of the disc by the belt conveyor and move with the working of pan pelletizer. As the disc rotates, compost material will rolls in the disc and gradually combine with each other to form into particles. In this process, if you add some binder (such as water, etc) by spray device, they will convert to rounded fertilizer pellets faster. Because of centrifugal force, the sheep manure pellets which meet required size will discharge out of the machine continuously from the bottom of the disc. The small particles will continue to stick together with the newly added material to roll and grow until they are qualified.

Roller Extrusion Granulator For Dry granulation of sheep manure compost

Double roller extrusion granulator can granulate sheep waste compost at normal temperature, one-time forming. Because of nearly no water involved, it don’t need any dryer and cooler. So there is a less investment in equipment and good economic benefits. In addition, the double-roller extrusion pelletizer has wide applicability. It can produce various various concentration and types of fertilizers, such as organic fertilizer, inorganic fertilizer, biological fertilizer, NPK fertilizer and so on. Moreover, you also can use it can in chemical industry, feed, coal, metallurgy and so on.

How Much Profit Can 1 Ton of Sheep Manure Organic Fertilizer Make?

How much profit can 1 ton of sheep manure organic fertilizer make? In fact, there are certain price differences between countries. The purchase price of about 1 ton of sheep manure is about RMB 80. After treatment, about 300-500 kilograms of finished organic fertilizer can be processed. The price of finished sheep manure organic fertilizer is about RMB 800 per ton, that is, it can be sold for 400 yuan. The profit per ton of demolition costs and other expenses is also more than 200 yuan. The organic fertilizer processing plant is a tax-free enterprise and a high-tech industry supported by the state. Therefore, there is a lot of room for development in terms of the prospects of the organic fertilizer industry and the profit market.

How to Choose a Suitable Sheep Manure Organic Fertilizer Production Line?

First of all, depending on the place of origin, the organic fertilizer production line is a large-scale mechanical equipment, which needs to be carefully considered when purchasing. So if you want to make a comparison, you must come to a place with more production areas, that is Zhengzhou, Henan. Only here is where manufacturers gather, and manufacturers in other regions are relatively scattered.

Secondly, the most direct way to see the strength of the manufacturer is to inspect and visit, which is clear at a glance. Shunxin covers an area of more than 30 acres and is a reliable large-scale organic fertilizer equipment manufacturer.

Looking at the service, our company has a complete pre-sale, sale and after-sales service. Provide factory construction guidance, production

technical support, equipment maintenance technology, etc.

Error: Contact form not found.