What Raw Materials are Needed to Produce Compound Fertilizer?

For compound fertilizer production, suitable chemical material using is important. It is closely related to the effect of final complex fertilizer you produce. Compound fertilizers usually contain two or more nutrients in nitrogen, phosphorus and potassium. So you can use the following chemical materials to prepare your compound fertilizer.

Nitrogen

Nitrogen can make the leaves of the plant large and bright green, so that the leaves can slow down senescence, and the yield is high. It often used in production for fast growth of plants. Therefore, we need to apply more nitrogen fertilizer to leafy vegetables. If you have urea, ammonium sulfate, ammonium bicarbonate, ammonium chloride, etc., they are good providers of nitrogen element.

Phosphorus

Phosphorus enables normal crop metabolism and good plant development. At the same time, it improves the drought resistance and cold resistance of crops, and matures earlier. The main varieties of phosphate fertilizers are superphosphate, double superphosphate, calcium and magnesium phosphate fertilizers. In addition, phosphate rock powder, steel slag phosphate fertilizer, defluorinated phosphate fertilizer, and bone meal are also phosphate fertilizers.

Potassium

Potassium can strengthen the photosynthesis of plants, make the stems tough, resist lodging, and make the seeds plump. Therefore, it plays an important role in the healthy growth of crops anf plants. The main potash fertilizer materials can be potassium sulfate, potassium chloride and plant ash. They can help you make compound fertilizer with rich potassium element.

What Types of Compound Fertilizer Production Lines Can You Choose?

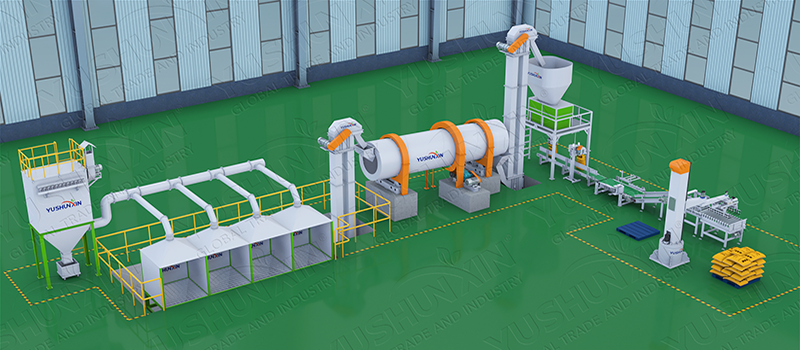

NPK Compound Fertilizer Mixing Line

If you want to produce compound fertilizer in a simple process, NPK mixing system is a wise choice. Compared with NPK powder to granules line, this system only contains several fertilizer machines. Batching system, BB fertilizer mixer and fertilizer packaging scale. This is also the reason why it can help you produce high-quality NPK compound fertilizer at a lower cost. In addition, even a 20 t/h NPK bulk blending system only needs an area of about 800-1000 ㎡ for installation (reference).

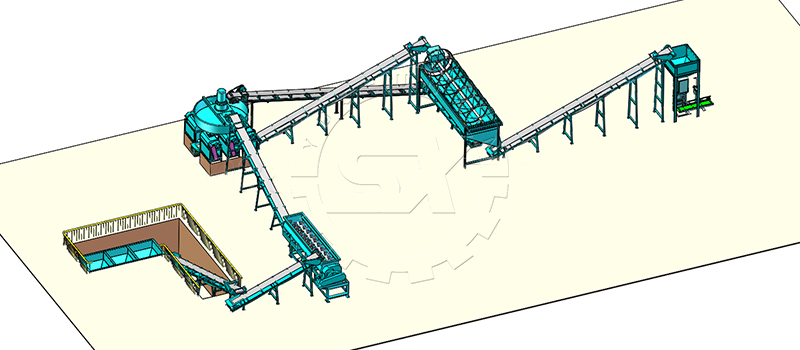

NPK Compound Fertilizer Dry Granulation Factory

NPK fertilizer is a popular choice for compound fertilizer production. And most fertilizer manufacturers are prone to make NPK fertilizer in granular shape. For this, we recommend you choose compound fertilizer production line with double roller granulator. Since the roller extrusion granulator belongs to dry granulation, you can package the NPK pellets directly without drying and cooling. This means you can save the money on dryer and cooler, fuel, energy consumption, etc while making higher profits.

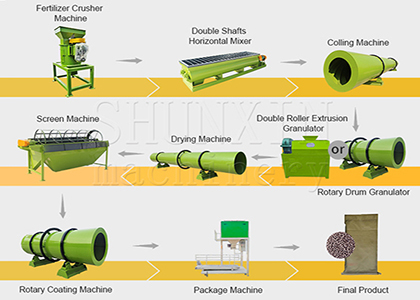

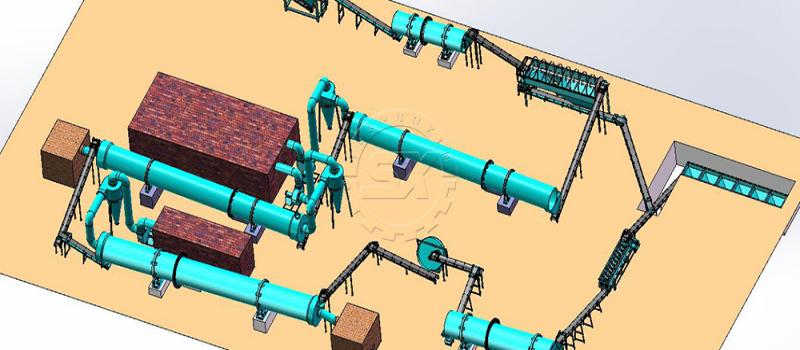

Effective Fertilizer to Granules Compound Fertilizer Production Line

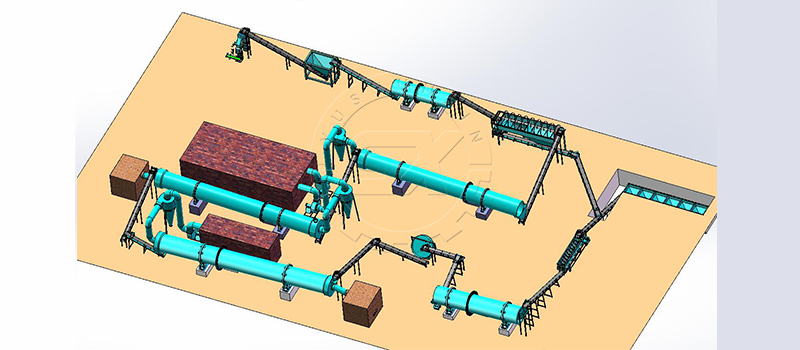

However, for complex fertilizer making with a capacity of 20-30 t/h and even 50 t/h, rotary drum granulation line is an better option. This business plan is designed for large scale chemical fertilizer production. Taking into account the needs of large-scale compound fertilizer processing, this production line uses a rotary drum granulator for granulation, which can prepare 30 tons of compound fertilizer pellets per hour. Moreover, it adopts wet granulation method, which can make fertilizer granules with a lower possibility of pulverization.

Equipment Configurations for Your Powdery Compound Fertilizer Manufacturing Plant

Compound Fertilizer Crushers

For chemical materials crushing, SX can provide you with urea crusher, cage shredder and chain grinder. Among them, urea crushing equipment can grind your chemical material into finer powder with a particle size of 0.3-0.5 mm. Cage shredder has a higher capacity, which can reach 10 t/h. Differently, chain grinder is widely used in returned materials pulvarization.

Dynamic Batching Machine

The dynamic batching system employs computer control. Automatic batching, quantitative measurement, high measurement accuracy, easy operation and reliable operation. In addition, we can equip it with material hopper according to your requirements, including number and size. And we design each material silo with a belt scale, so it can transport various chemical materials quickly and precisely.

Double Shafts Horizontal Mixer

Why do you need to add a fertilizer blender? This is because the material coming out of the batching machine has a unevenly distribution If you granulate directly, the distribution of nutrients in fertilizer granules is uneven. Some elements are abundant, and some are even missing. So the mixer is an indispensable step.

Our double shafts horizontal mixer uses a double-shaft design to make the material more evenly mixed. Generally, during working, the helical blades on double shafts will rotate in opposite directions to mix materials evenly. Moreover, the stirring blade is made of high-strength wear-resistant material, which has a longer service life.

Powder Screening machine

In order to producing powder chemical fertilizer with a higher purity and quality, it is necessary to sieve powdery compound fertilizer after crushing. powder fertilizer screen will separate qualified powder from the large particle size and waste likes cigarette butt, small stones, etc. In this process, you also can returned unqualified material to re-crush. So you can fully makes use of all chemical materials without waste.

Packing Machine

We has professional machine for powder compound fertilizer packaging. For more convenient powdery fertilizer bagging, SX especially designs large slope feeding port and screw pushing part. In addition, this machine adopts imported sensors, the measurement accuracy is lower than 2 ‰. So its packing speed is fast and the packing precision is high.

What Is the Process of Manufacturing Granular Compound Fertilizers?

How to Start Your Compound Fertilizer Company?

There are a number of issues that you need to consider in order to set up a complete fertilizer production line. For example: First, you should plan the site. How big is the site? Second, what kind of raw material is needed? Are there sufficient raw materials? Finally, what equipment is required? How much equipment is needed? Perhaps you do not know any of this. Or you already have the raw materials but don’t know how to start, so finding a professional compound fertilizer equipment supplier is crucial.

Here, SX is an ideal choice for you. We can provide you not only with equipment, but also with technical services. In addition, SX can give you program guidance and the right equipment for you. We have professional cartographers who can help you draw the layout of the site equipment and other issues. Secondly, you can ask us any questions you have and we will answer them patiently. This can be a lengthy process and not something that can be resolved in an instant. You may, of course, come and see our factory, and you are very welcome to visit.

How much does the Compound Fertilizer Plant Cost?

There are many factors to consider when you want to produce a fertilizer compound, but cost must be the first consideration for most customers. So how much does it cost to build a complete fertilizer production line? This varies depending on the size of the production line and the cost of materials. Among them, the price of the machine is a factor you pay particular attention to. So what are the advantages of Sunxin in terms of price? First, we will recommend the most suitable machine based on your budget cost. Secondly, we will have discounts and promotions on some major holidays. Compared with other countries, YUSHUNXIN has a economical price.

Error: Contact form not found.