What Machines to be Use to Convert Cow Dung in to Organic Compost?

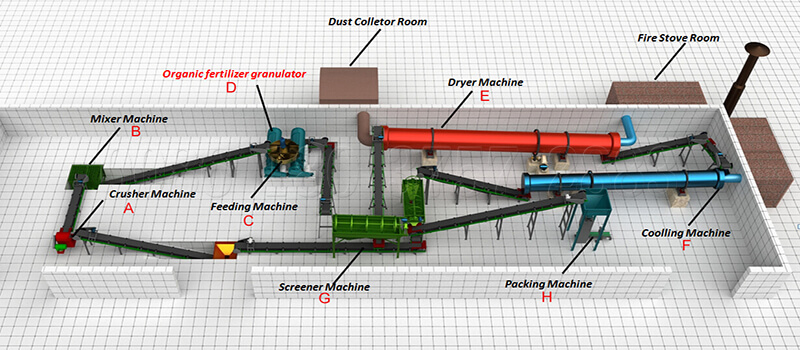

Cow dung is one of the most common farmyard manures, and the output of cow dung is very large. On average, a cow produces about 20 kilograms of manure a day, and a 50-head cattle farm produces about one ton a day. What do you do with so much cow manure if you have a cow manure farm of a few thousand cows? Cow dung is rich in organic matter content and various nutrients required by crops, which has a good effect on increasing crop yields and soil fertility. For many livestock farmers, pelleting your cow waste is the most profitable option. On the one hand, this solves the problem of cow dung disposal. On the other hand, it is profitable. How do you turn your cow dung into organic fertilizer pellets? The simple steps is:

- Adding excipients

- Composting

- Granulating

- Drying and cooling

- Packaging

This is an indispensable step in the production of organic fertilizers. Of course, there are other steps. A complete cow dung organic fertilizer production line requires more steps.

Is it Profitable to Make Commercial Fertilizer by Cow Dung Pellet Making Machine?

Before you consider the granulation of cow dung, the first thing that comes to mind is, is the cow dung suitable for granulation? Is cow dung organic fertilizer profitable? The answer is yes. Cow manure, like many other animal dung, is rich in nitrogen, phosphorus and potassium. It is an excellent raw material for making organic fertilizers. However, fresh cow dung has a high water content and cannot be directly granulated. Before you granulate, you need to compost cow manure. If you have thousands of cows, you might consider turning the manure into commercial fertilizer pellets. First of all, dealing with this cow dung is a headache. Secondly, if cow dung is not properly disposed of, it can cause pollution to the environment. So, making organic fertilizer is your best bet for dealing with cow manure.

How Many Kinds of Cow Manure Fertilizer Pellet Machines Can You Choose in ShunXin?

Disc Granulator of Different Scale Production

If your cow dung has a lot of moisture, a disc granulator is the right choice. And the disc granulator has different capacities of 0.02-6t/h to choose from. The disc granulator is one of the most widely used granulators. It can not only be used for granulation of cow dung, but also many other industrial products can be granulated by disc granulator.

The disc granulator is a type of wet granulation. First, you should add water or steam to bond the powered dry material. Second, through the high speed rotation of the granulator, the granules in the pan squeeze and roll each other. Finally, they become spherical granules. In addition, the pan granulator is driven by motor and reducer drive. With the continuous rotation of the motor, the material continues to enter, it can achieve mass production. During the operation of the machine, the material rises with the pan, and the material is also moves down due to its own gravity. At the same time, the material is constantly thrown to the edge of the pan by the centrifugal force. The materials are from large granules to small granules under the action of these forces.

1-30t/h Rotary Drum Granulator

Like most rotary drum granulators, our granulator also consists of a rotary drum, two riding rings and their bases, a large gear guard, the driving device and the machine base. It doesn’t sound like much, but these are the basic components of a rotary drum granulator. In fact, our rotary drum granulator has some special designs. It is these special designs that make our rotary drum granulators the choice of many fertilizer manufacturers. It is also a granulator equipped with many organic fertilizer, compound fertilizer and compound fertilizer production lines.

When you have hundreds of thousands of cattle or more, then you need to consider building a cow dung organic fertilizer production line. Which granulator is fitting for cow dung organic fertilizer production line? The answer is a large-capacity cow dung granulator. Our rotary drum granulator can handle 1-30t/h of cow dung per hour. You can choose the right size drum granulator according to the output of cow dung.

The drum granulator is installed in the production line, with high granulation efficiency and large processing capacity. Our drum granulators are available in many special designs. On the outside of the cylinder, there is a circular hole. With the rotation of the cylinder, the upper small hammer hits the system, on the one hand, it can prevent the material from sticking to the wall; on the other hand, it can make full use of the material. Externally, our drum granulator has gears connected with the barrel to ensure the stability of the barrel rotating at high speed. A drum granulator can turn your cow manure into spherical fertilizer granules.

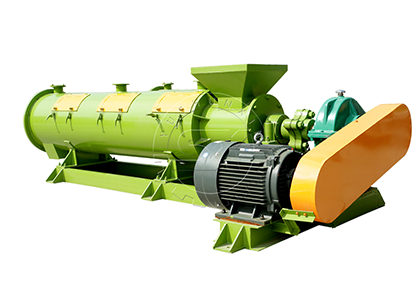

New Type Organic Fertilizer Granulator with High Granulation Rate

The new organic fertilizer granulator is a granulator specially designed for organic fertilizers. All kinds of raw materials for making organic fertilizers can be granulated with the new organic fertilizer granulator. It has different capacities to choose from. Whether it is a small organic fertilizer granulator or a large organic fertilizer granulator, you can use the new organic fertilizer granulator. Our new type organic fertilizer granulator has many special features in its design. First of all, high-strength wear-resistant materials are used on some special parts to ensure that the granulator can run for a long time. Secondly, in the design of the rack base, we use a triangular support design. Finally, there is an observation window in the barrel of the granulator. On the one hand, the granulation situation can be observed in time. On the other hand, it is convenient for the inspection and maintenance of the machine. It is because of these special designs that many customers choose SX.

How Do We Design Our Cow Manure Pellet Making Machine in a High Quality?

Cow Manure Fertilizer Pan Granulator

Different Models

For different production capacity, we have different models of pan granulators. If your raw materials are very small, we can give you a small granulator. There are small granulators with 0.5T/h output, and a large disc granulator with a 5T/h output. Of course, it is also appropriate to put the disc granulators on the production line.

Stable Base

When the disc granulator is running, the force is very strong. So it needs a stable and strong base to support. First of all, the two sides of the base of our granulators use the triangular structure design to make the equipment run more stable. Secondly, our framework is made of square steel, which has a strong supporting effect in shape and material. This also increases the stability of equipment operation.

Anti-Stick Wall Device

There is a scraper on the disc,. When the discs are turning, the scraper will remove the materials that may stick to the plate wall. What are the benefits of it? On the one hand, it can keep your granules clean and you do not need to clean the granulator every day. On the other hand, it can reduce the consumption of raw materials and prevent the waste of materials.

Cow Dung Fertilizer Rotary Drum Granulator

Driving Device

The drive system of the rotary drum granulator mainly includes a motor, a reducer and a drive roller. The motor powers the rotation of the drum. The motor output is decelerated through the reduction gear, and the drum is driven to rotate through the reduction gear .

Rotary Drum

The drum is a pelletizing container. It is a cylindrical shape made of steel plate. It has a rubber plate attached to the inside to prevent highly viscous materials from sticking to the cylinder wall. The length and diameter of the drum depend on the quality requirements of the granulated material and the quality requirements of the granulated particles.

Gear Teeth

The gear teeth mainly include two parts, large gear guard and riding ring. The large gear guard is fixed on the rotary drum. Its main function is to maintain the position of the rotary drum. The riding ring is connected to the riding ring support, symmetrical on both sides of the drum. Its main function is to rotate the drum.

Cow Litter New Type Organic Fertilizer Granulator

High-strength Wear-resistant Material

In order to ensure the long-term operation of the stirring tooth granulator. We use some special material on some important parts. The material for the stirring teeth of our granulators is manganese steel. This steel is able to withstand huge impacts, extrusions, abrasions, etc. The teeth head of the granulator are made of carbide. You can disassemble and replace it. It is these special materials that have led many customers to choose SX.

Solid Triangular Base

In the design of the rack base, we use a triangular support design. Triangles are inherently stable. Strong support is essential for the smooth operation of the granulator in the presence of large rotational forces. And the use of square steel material makes the machine run more smoothly.

Observation Window

There is an observation window in the barrel of the granulator. On the one hand, the granulation situation can be observed in time. On the other hand, it is convenient for the inspection and maintenance of the machine.

How to Choose the Right Cow Dung Pellet Making Machine?

Choose a Formal Enterprise

As a mature organic fertilizer equipment manufacturer, after more than ten years of development, we have achieved one-stop services such as design, manufacture, installation, commissioning and technical training. Over the years, our equipment has been exported to many overseas countries, and our products have been distributed in China and all over the world. You can fully trust our enterprise.

Choose Sturdy and Durable Materials

Our products have developed with the development of the times and have obtained many new utility patent certificates. We also continue to absorb various foreign precision accessories, such as Siemens, ABB, etc., to make our equipment last longer and more stable. In the performance of the rotary drum granulator material, we have a great advantage.

Choose the Right Price

Compared with the high prices in countries such as Europe, our equipment has a great price advantage. During some holidays and the end of the year, we will give discounts. And we are happy to send you some specialties from China. So if you are interested in our rotary drum granulator, contact us!

What Should You Consider When You Choose SX Cow Dung Pellet Making Machine?

When you buy a granulator, you must consider the performance, capacity, and suitability of the machine. So what do you need to consider when buying our wet granulator?

Size and Capacity

First, you need to decide what capacity machine you want to buy. From wet granulator, we have granulator ranging from 0.02-30t/h. You can decide based on the size of your raw material for granulation. Of course, if you are not sure what specification of granulator to buy, you can leave a message to contact us. We will have a professional reply from the factory. In addition, you also need to confirm that your budgeted site area is large enough to accommodate our pelletizer.

Power Consumption and Energy Consumption

Different granulators have different motor powers. Different sizes of the same granulator will also have different motor powers. Among the wet granulators, the motor power of the disc granulator is the smallest, and the motor power of the disc granulator with an output of 0.02-0.05t/h is 0.55kw. For the same output of 1-3t/h, the motor power of the disc granulator is about 7.5kw, the power of the drum granulator is 5.5kw, and the total power of the tooth stirring granulator is about 55kw. When we choose a granulator, we will definitely choose a granulator with a smaller power, which will help us save the cost of granulation.

The Quality of The Machine

First of all, the granulator should be ISO certified. Secondly, in the selection of materials, materials with high wear resistance should be selected. for the long-term operation of the machine. On the one hand, our pelletizers are all inspected for quality before shipment. On the other hand, in the selection of materials, some vulnerable parts of our machines use special materials. For example, the stirring teeth of the new type organic fertilizer granulator are made of manganese steel, which can withstand huge pressure, impact and wear. In the material of the machine frame, we also use wear-resistant steel to ensure consistent thickness.

Error: Contact form not found.