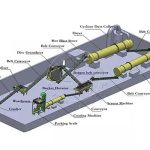

Wet granulation is a good method to make quality fertilizer granules, whether you plan to start an organic fertilizer making business or a compound fertilizer production project. Different from dry granulation, wet granulation make fertilizer power into pellets by adding water or adhesives. They can greatly inprove the adhension between fertilizer materials and make them combine together faster and more firmly. Then as a professional fertilizer equipment manufacturer, we can provide you the quality equipment for wet granulation and the best solution for your fertilizer granule making plant.

3 Steps in the wet granulation of fertilizer

The wet granulation process of fertilizer is generally divided into 3 steps.

Fertilizer material power wetting

As the name suggests, wet granulation mainly makes use of liquid to make fertilizer material powder convert to granules quickly. So the first step is wetting your fertilizer materials. But, when and how to finish it easily and perfectly? Here, our disc granulator and drum pelletizer have professional spray device space. Which can control water or other agent adding precisely. Or, you can choose to move liquid spray design to the fertilizer mixing machine.

Agglomeration of compost or NPK granules

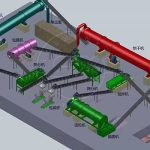

Then, the most important step for compost and NPK powder to fertilizer pellets is granulation with machine. In order to fully meet your requirements of quality fertilizer granules manufacturing, we especially design various wet granulation machines for your choice. Besides disc pan granulation machine and rotary drum granulator, there is also new type organic fertilizer pellet equipment. From 1-20 t/h capacity, both organic fertilizer granule making and NPK compound fertilizer pellet production, small or large plant area, etc, you can get the best fertilizer equipment of wet granulation.

Fertilizer pellets drying

However, to make commercial fertilizer you produce easier to transport, store and use, it is necessary to reduce the moisture. Therefore, it is advisable to dry the finished wet granulation fertilizer pellets before packaging. Here, we can offer you suitable fertilizer dryer. The machine can dry a large amount of compost and NPK granule to below 10% water content quickly.

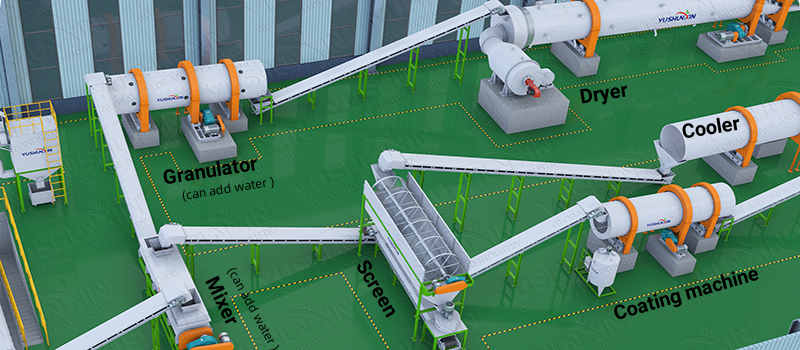

What Wet Granulation Machine is suitable for you?

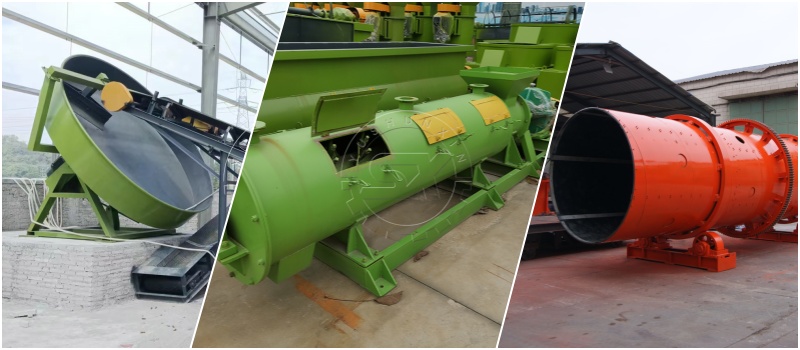

As a professional fertilizer equipment manufacturer, we can offer you 3 types of wet granulation machine for your fertilizer pellet making project.

Pan pellet machine for 1-6 t/h small scale wet fertilizer granulation

If you need a economical wet granulation equipment for small scale fertilizer plant, disc granulator your best choice. It can fully meet your 1-6 t/h organic or NPK fertilizer pellets manufacturing. And its granulation rate is over 93%. This machine mainly makes use of the rotation of the disc to make raw material combine and form into granules. During the operation of the machine, the material rises with the pan, then falls because of its own gravity and combines with each other. At the same time, under the action of the the centrifugal force, fertilizer pellet with reach required size will move to the pan edge and be discharged. In addition, the pan granulator is driven by motor and reducer drive.

Rotary Drum Granulator for 10-30 t/h large scale wet pellet making

However, over 10 t/h fertilizer granulation plant setup, we recommend you buy our drum granulator. Its maximum fertilizer granule output reaches to 30 t/h. Rotary drum design makes the machine granulate more fertilizer. In addition, in order to reduce the possibility of wall sticking, we especially design material lifting plates and cleaning holes. The former prevents fertilizer powder from being pressed together in large quantities. While the latter will shake off the wall sticking material after hammer hitting.

New Type Granulator For high strength organic fertilizer particles production

How to make fertilizer pellets with a higher hardness? For organic fertilizer granules production, the key is our new type organic fertilizer granulator. Compared making material roll into pellet naturally, it utilizes the friction between stirring teeth and the body wall to turn compost and NPK into particles. Here, you can adjust the size of the particle diameter according to the rotational speed of the rotor. The higher the rotational speed, the smaller the particles. Before granulation, the moisture content of the raw material should be between 20% and 40%. The diameter of the finished particles is generally between 3-5mm.

The main technical parameters of the disc granulator are as follows:

| Wet Granulation Equipment | Capacity (T/H) | Feeding Material Moisture | Application |

| Pan pellet machine | 0.02-6 | 20%-40% | organic & compound fertilizer granulation |

| Rotary Drum Granulator | 1-30 | 20%-40% | organic & compound fertilizer granulation |

| New type granulator | 1-8 | 20%-40% | organic fertilizer granulation |

what are the difference between the wet granulation and dry granulation?

In general, there are two granulation methods that commonly used in fertilizer production. Besides wet granulation equipment, it also has dry granulation machine. What are the differences between them?

More round fertilizer pellet making – better fluidity

Wet granulation changes the properties of formulation ingredients and overcomes the defects of extrusion granulation. The main advantage of wet granulation is that it forms granules and is more spherical than powder and therefore has better flow properties. And the spherical shape of wet granulation can be easier to pack.

Granulating fertilizer with water – less dust pollution

In the wet granulation process, water or adhesive needs to be sprayed, which prevents dust from flying and reduces the risk of dust injury to workers.

Larger output range – 1- 30 t/h

The output of dry granulator is 1-6t/h, while the maximum capacity of wet granulator can reach 30t/h. Compared with dry granulators, wet granulators are more suitable for large fertilizer production lines. And there are many types of wet granulators.

controlling fertilizer pellets easier

Wet granulation can control the diameter of the particles according to the moisture content. If the particles are larger, the moisture content in the raw material can be reduced. If the particles are too small, the moisture content in the raw material can be increased.

Get more details of wet and dry fertilizer granulation machines

How Does a Wet Granulator Form Denser and Uniform Granules?

Wet granulators produce uniform and dense granules through the process of agglomeration. The process of agglomeration involves the addition of moisture or other adhesives. When it comes to binders, water is the most convenient and harmless adhesives. Before adding other binders, you need to test whether they will react to your raw materials. Generally speaking, most organic fertilizer granulation will use wet granulator.

When is suitable to use wet granulation equipment in fertilizer pellet making

The raw materials of wet granulation are suitable for materials that are not sensitive to moisture and temperature. When the moisture content of your granulation raw material is high, you can directly carry out wet granulation. Like fermented poultry manure, with a moisture content of about 30%, wet granulation can be carried out directly. Generally, large fertilizer production lines and manufacturers use wet granulators. Because compared to the dry granulator, the equipment for wet granulation has a larger output. Most organic fertilizer raw materials are not completely dry after fermentation, and few can be directly granulated with a dry granulator. However, it can be granulated with a wet granulator.

What Should You Consider When You Choose SX Wet Granulator?

When you buy a granulator, you must consider the performance, capacity, and suitability of the machine. So what do you need to consider when buying our wet granulator?

Size and Capacity

First, you need to decide what capacity machine you want to buy. From wet granulator, we have granulator ranging from 0.5-30t/h. You can decide based on the size of your raw material for granulation. Of course, if you are not sure what specification of granulator to buy, you can leave a message to contact us. We will have a professional reply from the factory. In addition, you also need to confirm that your budgeted site area is large enough to accommodate our pelletizer.

Power Consumption and Energy Consumption

Different granulators have different motor powers. Different sizes of the same granulator will also have different motor powers. Among the wet granulators, the motor power of the disc granulator is the smallest, and the motor power of the disc granulator with an output of 0.02-0.05t/h is 0.55kw. For the same output of 1-3t/h, the motor power of the disc granulator is about 7.5kw, the power of the drum granulator is 5.5kw, and the total power of the tooth stirring granulator is about 55kw. When we choose a granulator, we will definitely choose a granulator with a smaller power, which will help us save the cost of granulation.

The Quality of The Machine

First of all, the granulator should be ISO certified. Secondly, in the selection of materials, materials with high wear resistance should be selected. for the long-term operation of the machine. On the one hand, our pelletizers are all inspected for quality before shipment. On the other hand, in the selection of materials, some vulnerable parts of our machines use special materials. For example, the stirring teeth of the stirring tooth granulator are made of manganese steel, which can withstand huge pressure, impact and wear. In the material of the machine frame, we also use wear-resistant steel to ensure consistent thickness.

Error: Contact form not found.