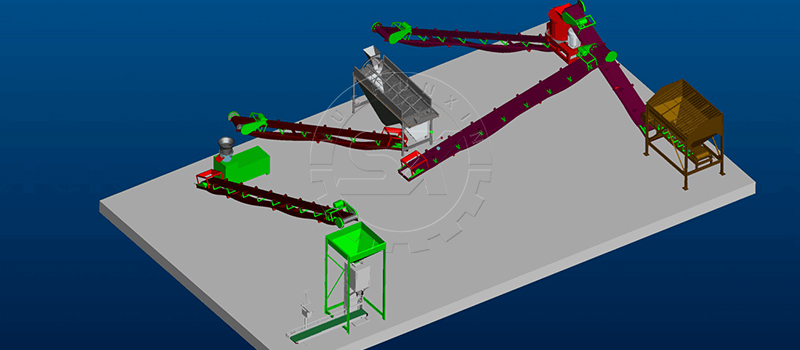

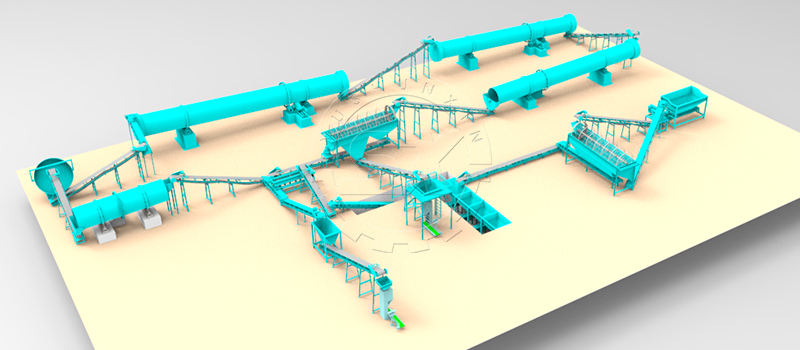

For chicken farm operation, manure management is an item you must focus on. For this, it is an ideal choice to turn broiler manure into organic fertilizer. But are there low cost commercial solutions for broiler farms manure management? Partial farm owners don’t have enough budget. Of course. You can buy organic fertilizer making line, which consist of manure dehydrator, aerobic composter and granulation machine.

Contact use for your own organic fertilizer making system immediately!

How does a dehydrator help you dispose of chicken manure into fertilizer?

For organic fertilizer making, it is essential to control moisture content of broiler farms manure. If the water content of your chicken poop material is higher than 60%, we recommend you process it with our manure dehydrator first. Because excessive moisture will affect chicken manure composting effect. But our fertilizer dewatering machine can help you reduce the chicken waste moisture to 30% in a short time.

How to choose a suitable dehydrator for broiler farms manure management?

In general, you need to consider chicken farm waste moisture content. When it is between 50% and 80%, we recommend you choose screw type dewatering equipment. However, over 80%, it is advisable to use SX inclined screen solid-liquid separator. This machine will separate liquid from solid chicken dung before screw extrusion. So it is suitable for drying higher moisture content manure.

Why is compost machine necessary for broiler farms manure management?

When you plan to produce chicken manure fertilizer, composting is a necessary step. Why? Because in this process, microorganisms in manure will decompose organic matter and generate a large amount of heat to kill harmful substances. Such as bad bacteria, pest eggs and grass seeds. In natural conditions, chicken manure composting will take 2-3 months. But using suitable fertilizer compost equipment, you can finish it within 20 days.

Which manure composting equipment is suitable for you?

If you have a low-cost budget, we recommend you windrow compost turner. In addition, it is advisable to buy trench type composter for indoor aerobic fermentation of chicken poop and purchase fermentation tank for full automatic composting.

How to deal with chicken manure after composting?

You can choose to store it for a period of time and wait for the curing period to end. Certainly, if you want to develop organic fertilizer production business, we recommend you convert broiler manure compost powder to fertilizer granules.

Contact use for your own organic fertilizer making system immediately!

How to make chicken manure into fertilizer granules?

In the process of chicken waste fertilizer pellets manufacturing, the most important thing is to choose a suitable granulator. And if you want to granulate chicken manure at a low cost, we recommend you flat die pellet mill and disc granulator. The former adopts dry granulation method and can produce 1-1.5 tons of chicken dung pellets per hour. At the same time, the latter employs wet granulation method and can prepare 1-6 tons of manure particles per hour.

What Is The Difference Between Dry Granulation And Wet Granulation?

In dry granulation of chicken manure, there is nearly no water involved. For one thing, it makes use of extrusion between rotating roller and mold to turn power compost to granules. For another, its required feeding moisture content is below 10%. So if you want to upgrade the chicken manure fertilizer making line, you can save your money on fertilizer drying and cooling.

But provided you want to produce round chicken manure fertilizer pellets, disc wet granulator is a better choice. Using it, you can freely choose to prepare 1-8 mm organic fertilizer particles. Then because of wet granulation method, only by adjusting moisture, you can regulate pellet size according to your will. Moreover, for more convenient granulation water content changing, we especially design spray device for pan pelletizer.

How to produce commercial chicken manure fertilizer pellets better?

You can chose add a crusher before granulator. It can grind chicken poop compost into fine powder, which makes granulation easier. Moreover, after granulation, you can send fertilizer pellets to rotary screener. This fertilizer equipment can sort qualified pellets and the unqualified. So you can further improve the quality of final fertilizer.

Error: Contact form not found.