Organic fertilizer granulator machine is mainly used to granulate various organic fertilizer pellets after fermenting. Organic fertilizer granulator has another name, that is wet type granulator. Because organic fertilizer pellet mill adopts wet type granulation technology. That means you need to add adhesives or liquids to increase the adhesiveness of materials. If you have too much organic waste and don’t know how to dispose them, you can use an organic fertilizer granulator to convert them into organic fertilizer. With organic fertilizer granulation machine, you not only can dispose organic waste, but also can earn more money from it.

Small organic fertilizer granules machine for manufacturing organic fertilizer raw material

Want to set up a small pelleted fertilizer factory? For building a small organic fertilizer granulation plant, what kind of organic fertilizer pellet machine should be used? To be honest, if you ae going to build a small-scale organic fertilizer production factory, you had better have a small-scale granulation equipment for disposing organic fertilizer raw material. According to your requirements, we have many mini organic fertilizer pellets granulators for you to choose. For example, we provide small pan pelletizer with the capacity is 0.5-0.8t/h, the model is TDYZ-1500, the edge height is 300mm, and the rotary speed is 21r/min. In addition, we also have the mini organic fertilizer pellet mill with the capacity is 0.8, 1.2, 1.5,2.0 and so on. Therefore, you can choose the suitable organic fertilizer pelletizer to meet your requirements. And if you don’t find the machine what you need, we can also customize it for you.

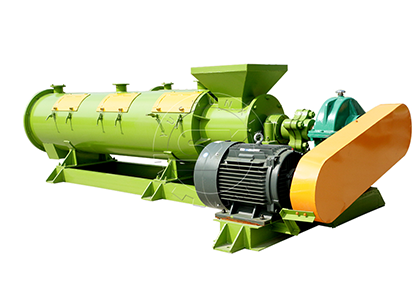

Quick compost granulator machine for sale

In our organic fertilizer production line manufacturing factory, we not only have mini organic fertilizer pelletizer, but also have quick organic compost granulator machine for sale. That is organic fertilizer rotary drum stirring granulator. This wet type stirring pellet mill makes use of high-speed rotary mechanical agitation force and the resulting aerodynamic force to produce granular organic fertilizer. That can make fine powder material continuously achieve the process of mixing, granulating, balling and densification in the machine, so as to achieve the purpose of granulating. With the help of organic fertilizer rotary drum granulation machine, you can get the granular organic fertilizer as soon as possible. In addition, the hardness of particles formed by the rotary drum stirring pelletizer is much harder than other granulation equipment. And the fertilizer pellets made by organic fertilizer granulation machine is more beautiful. Meanwhile, this quick compost granulator machine has high granulation rate.

How much is an organic fertilizer granules machine?

In fact, the price of granulator machine for organic fertilizer depend on many factors. Here are the details.

The size of organic fertilizer granules machine. As mentioned above, we have small organic fertilizer granulator and large-scale fertilizer granulation equipment. Obviously, they have different prices, we promise that all of the price of organic granules making machines are affordable and reasonable.

Distance. Distance is another factor to affect the price of organic manure pellet making machine. You know, the longer the distance, the higher the freight.

The material. Our granular fertilizer making machine is made by stainless steel. Because the material quality is high, the granulation equipment has long service life. Therefore, if you want to buy high quality organic fertilizer granulator machine, you need pay more money on it.

What kind of organic fertilizer granulation technology adopted by us?

Generally speaking, there are different granulating technologies for both inorganic granular fertilizer and organic fertilizer particles. Our organic manure granular fertilizer pellet mill adopts wet type granulation technology to produce granulated fertilizer. Just as its name implies, wet type granulation means that you need to add some water or binder to increase the adhesiveness of the organic raw material. Then, with the help of centrifugal force, the organic fertilizer raw material will rotate into particles. And in order to get high quality fertilizer granules, the moisture content of raw material should be controlled over 20%. In the whole wet type granulation process, water content is the key factor to affect the pellets quality. Thus, you need pay more attention to the moisture content. In our fertilizer production line production plant, we also provide dry type granulation machine for making compound fertilizer granular fertilizer.

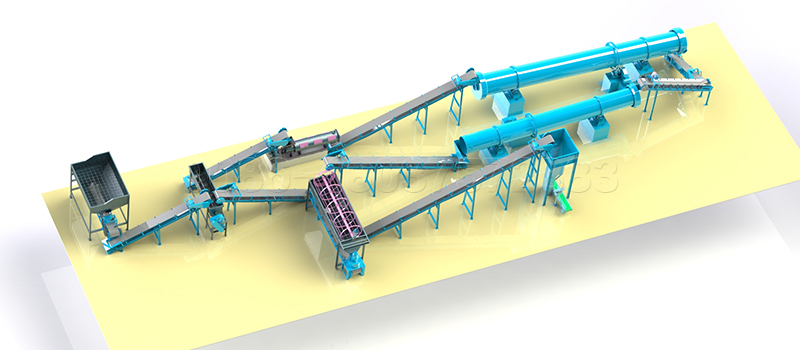

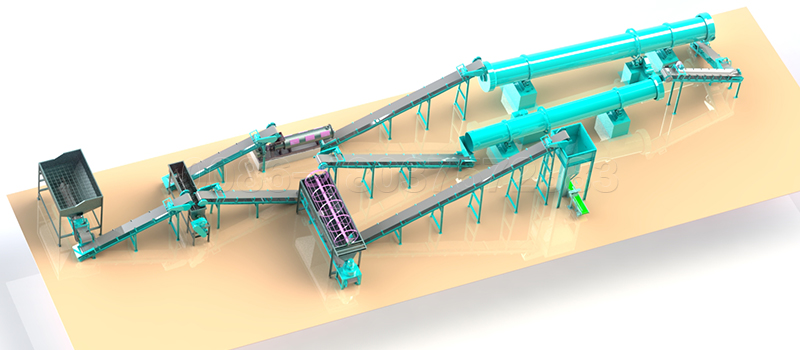

The whole production process of making organic fertilizer pellets from agriculture organic waste

For making granular organic fertilizer, it’s not enough just used a granulator. You should also use other fertilizer production equipment.

Dehydrating. Before making organic fertilizer, the water content should be controlled in 60%-65%. You need use a fertilizer solid-liquid separator machine to help you do that.

Fermenting. You can’t make organic fertilizer pellets with harmful microorganisms and pathogens. Fermenting equipment can kill these pathogens in a safe way. Our organic fertilizer compost turner may be your good choice.

Crushing. If you want to make granular organic fertilizer, you need to make powdery fertilizer. For converting lumpy fertilizer into powdery fertilizer, you had better use a crusher.

Granulating. For getting granular organic fertilizer, granulating is the most important part. Conveyor will be sent powdery fertilizer to organic fertilizer pellet mill for producing granular organic fertilizer.

Screening. In order to screen out the unqualify granular fertilizer, screening is an obbligato process.

Drying and cooling. These the processes for controlling the temperature of fertilizer pellets.

Packing. That is the step for packing finished organic fertilizer particles.

Here is the whole organic fertilizer pellet production line, this complete fertilizer pelletizing system can help you make the fertilizer pellets you want.

Applications of organic fertilizer granulator machine

Agricultural wastes Treatment. Most of agriculture wastes can be used to produce organic fertilizer pellets, such as leaves, straws, stalks, stover, roots, bean dregs, cottonseed meal, etc.

Livestock manures management. Almost organic fertilizer granulation plant adopts animal poop as organic fertilizer raw material. And animal poop also is perfect source of organic fertilizer. For example, chicken waste, cow dung, pig manure. horse poop can be made good fertilizer pellets. Organic fertilizer pellet machine is a perfect manure disposal equipment.

Industrial wastes disposal. The residues of organic material after processing. These are, vinasse, vinegar residue, candy pomace, furfural residue, cassava wastes and so on. If you have other organic fertilizer raw materials and don’t know if you can make fertilizer particles, feel free to contact us.

Error: Contact form not found.