How to improve powder granulation rate? This is an item most granulation plants pay attention to. The same as a client from India, who emailed to us on June 14th to inquire about quartz sand pellets making. This customer is from leading glass bottle manufacturing company in India, which has own quartz sand manufacturing plant. During the communication process, we learned that the buyer’s existing production line is equipped with a drum granulator. And he wanted to further improve the powder to pellet making rate. The following are the specific details of this case:

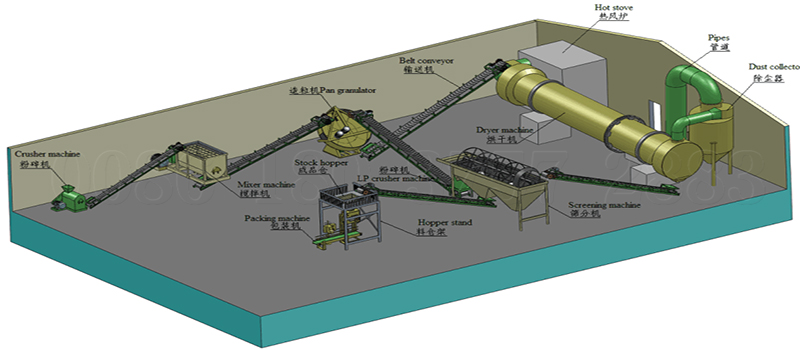

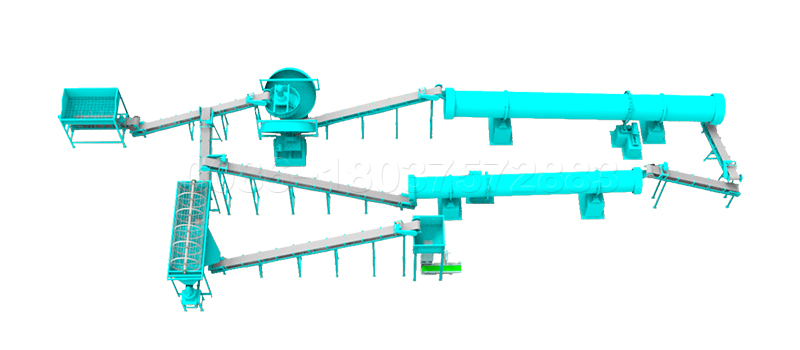

After detailed communication, we know that our client’s raw material is quartz sand powder. Additives are baking soda, sodium silicate solution and slaked stone.After we inquired about the client’s output and site, we know that the client’s output requirement is 5t/h, and the site is 40m*34m. And the client emphasized the problem of granulation rate. The client wants a granulator that meets the output and has a high granulation rate. So we sent the test machine video of the disc granulator to the client, and determined that the disc production line is the most suitable for the client’s requirements.

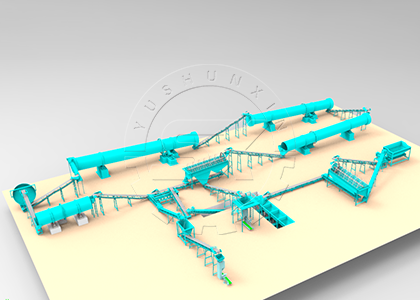

5t/h Disc Granulation Production Line

On June 29th, we sent the drawing of the complete disc granulator production line to the client. The client is worried that the effect of the disc granulator is not good, so we recommend the client to send raw materials to test the machine. The client asked us how many raw materials we need to send, and we sent the detailed raw material quantity to the client. However, due to the large quantity of raw materials, we suggest helping clients to purchase raw materials for trial operation.

On August 9th, the client decided to visit. After confirming the client’s visiting time and number of people, we decided to wait for the client to come and then test the machine. On August 20th, the client came to visit and conducted a test machine after visiting our factory. The effect of the test machine was very good. Later, we discussed some details with the client and made a quotation.

In September, the client raised some questions about the drawings, and our engineers gave answers. Later, the client asked 38 questions about the production line drawings. The client asked whether the production line would produce waste? We gave the answer that the output of the line is 100%, and the disc granulator can be covered with a cover so that no dust is generated. And we have designed a dust removal system for this production line, and the materials in the system can be recycled.

Among them, the client mentioned the business philosophy of the entire production line. We know that the client wants to know how to operate and install the entire production line. Our engineers will be there to guide the commissioning of the machine and train your staff how to operate and maintain it regularly. We inform clients that the machine manual will be provided with the machine when it is delivered. There will also be detailed machine operation and maintenance guidelines on it. In fact, the entire production line is highly automated, and the entire production line needs 3-4 workers: 1 for ingredients, 1 for feeding, 1 for furnace, and 1 for packaging.

After knowing all about the production line, the client decided to buy the whole production line. As our clients expect, the entire line consists of highly automated fertilizer making machines. With the help of automatic conveying system, the raw material can enter each fertilizer making machine without manual feeding. Hence, less effort enables our clients to manage commercial fertilizer plants, thereby reducing labor expenses.

What Can We Do For Client?

We treasure every client email we receive. Shunxin has professional personnel to communicate with clients. According to your raw materials and needs, we will recommend suitable machines and production line solutions for you. Of course, you can also ask us for quotations and product drawings. We will patiently answer your questions throughout the process. Of course, Shunxin also welcomes friends from all over the world to visit our factory. You can check this page to learn more about animal manure fertilizer manufacturing and get a solution for your fertilizer plant! https://organicfertilizerproductionline.com/